At one of the enterprises of the woodworking industry, steam dryers are widely used to dry round timber, wood, plywood and other materials to the required standard of moisture content. Our specialists noticed that thermodynamic and float steam traps from different manufacturers were used haphazardly to drain condensate at the plants. The technical staff estimated the efficiency of the condensate drainage equipment very approximately - if the steam consumption rises by one and a half times from the standard indicators, then it is time to replace the steam traps. At the same time, there were a number of other problems in the operation of the equipment:

- Installed models of float steam traps did not have a margin for a wider range of operating pressures. In the case of an increase in steam pressure and, accordingly, condensate, up to 14-15 bar g, the performance of condensate traps with an exhaust valve (orifis), designed to drain condensate with a pressure drop of maximum 13 bar g, was disrupted.

- Thermodynamic steam traps, due to their design features, did not have sufficient throughput capacity, since they are intended for drainage of steam pipelines, and are not suitable for continuous discharge of condensate from heat exchangers. There were problems with capacity due to the large amount of pollution, even the parallel installation of thermodynamic steam traps could not solve this problem 100%.

As a result, some steam traps let steam into the condensate line, while others, not letting in steam, also did not let condensate through, there was insufficient ventilation during start-up, creating a danger of air locks in the steam system. At start-up, the system was filled with condensate, which did not have time to be discharged, it was "airy", the heat exchange efficiency significantly decreased, and as a result, the stationary mode of operation was reached only on the third day, while with the correct operation of the condensate drains, and the rapid removal of air and condensate this process would take only a few hours. As a result, the enterprise suffers financial losses for three days due to excessive consumption of energy carriers and electricity, and at the same time does not manufacture products. But it shouldn't be so!

The engineers of OPEKS ENERGOSYSTEMA proposed to install float steam traps of the Japanese company YOSHITAKE - threaded type TSF-8-21 DN25 (Flanged version TSF-10F-21). This model reliably removes condensate at different pressure drops, up to 21 bar g. The maximum throughput is up to 2 tons of condensate per hour. These technical characteristics fully met the requirements of the chief power engineer of the woodworking plant, and at the same time had a larger margin of productivity.

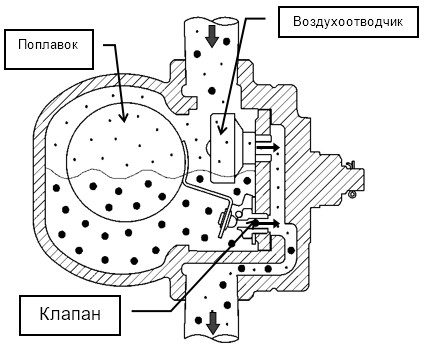

FIG. 1. Structure of the TSF-8 float steam trap

The picture shows the main parts of the steam trap and how it works. When the condensate fills the main cavity, the lever-type float rises (floats), opens the outlet valve, and condensate is continuously removed from the system without hindrance. A capsule thermostatic air vent is used for starting airing of the steam-condensate system. At lower temperatures of air and condensate (than steam), the working substance inside the capsule is in a compressed - liquid state. Air flows freely through the closed valve and is removed from the system. As the temperature rises, the substance inside the capsule evaporates, the volume increases, and the air vent stem closes the air valve.

FIG 2. Nominal Capacity of TSF-8 Steam Trap versus Differential Pressure

A significant advantage of YOSHITAKE float steam traps is the ability to mount both horizontally and vertically. You do not need to purchase another type of equipment for this. It will be enough to unscrew the 4 bolts of the top cover of the steam trap and rotate the base inner part by 90 degrees, put the cover back on the steam trap. This feature has several advantages:

- There is no need to purchase different models of steam traps for vertical and horizontal installation - one Yoshitake model works in both spatial positions.

- The Yoshitake float steam trap has a higher capacity than others for the same pipe diameter.

- In conditions of complex branching of the condensate pipeline system, this makes it possible to remove the condensate drain from the horizontal section and, after simple steps, install it on a vertical pipeline. Also vice versa.

The company that previously worked with the customer offered equipment that fixes some problems, but does not solve the problem as a whole. We have proposed a technical solution that, in combination, ensures reliable performance of the condensate drainage system:

- Universal float steam trap Yoshitake of higher capacity, on the same diameter of the pipeline, prevents the filling of the system with condensate;

- A properly selected float steam trap, equipped with a thermostatic air vent, allows the system to start up and ventilate much faster than a thermodynamic one, which slowly removes air;

- The YOSHITAKE TSF-8-21 model has a wide operating pressure range - the problem of insufficient condensate drainage rate at a high moisture content of the product is eliminated;

- The universal model YOSHITAKE TSF-8-21 is mounted on both horizontal and vertical pipe sections;

- Easy and Reliable Operation - The Yoshitake Trap consists of a minimum number of moving parts.

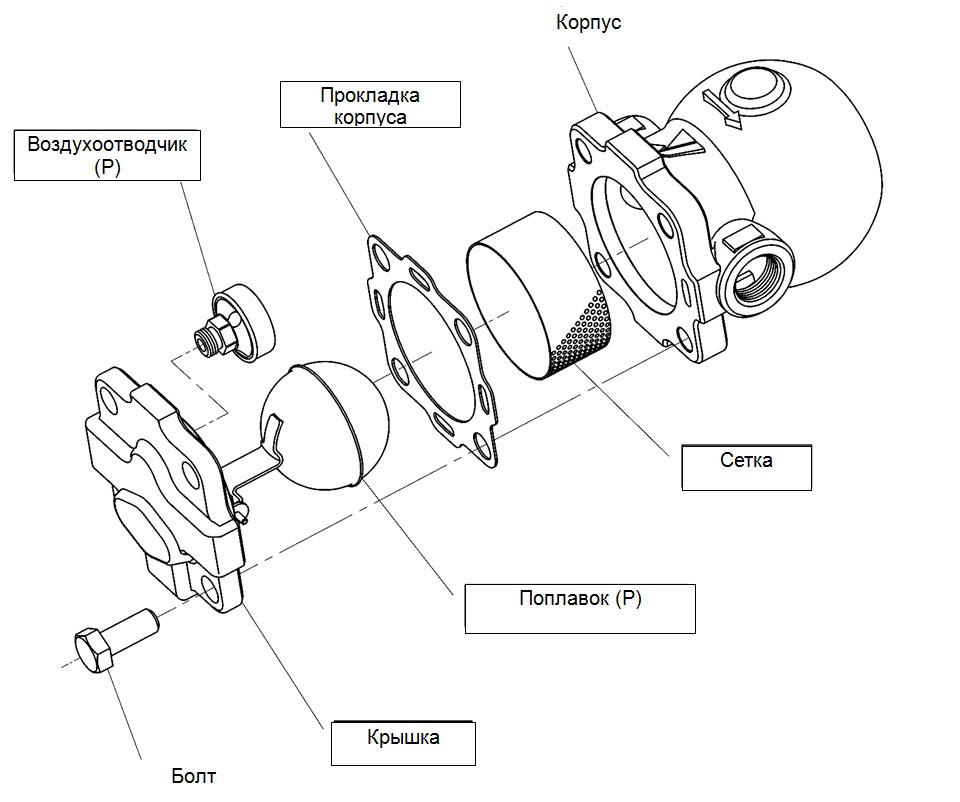

FIG 3. TSF-8 float steam trap disassembled

The YOSHITAKE TSF-8-21 float steam traps, selected and installed by OPEKS Power System engineers, ensured reliable operation of the equipment at the plant. This laid the foundation for future projects to modernize production systems!

FIG 4 TSF-8-21 float steam traps are packed prior to shipment to a wood processing plant!

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442