Since 1999, OPEKS Energosystems has begun fruitful cooperation with the largest manufacturer of brazed heat exchangers, the Swedish company SWEP International AB. Founded over 30 years ago by an ordinary engineer, SWEP has grown into a large company with factories in several countries around the world.

SWEP brazed plate heat exchangers have found their application in various areas of domestic and industrial equipment. Brazed heat exchangers have earned particular popularity due to their compact size, for their effective use in freon systems, as well as as heat exchangers for the hot water supply circuit in domestic boilers. The compactness is achieved by the absence of seals between the plates and, as a consequence, the absence of tightening bolts around the perimeter of the heat exchanger body. Among the wide range of SWEP heat exchangers, we highlight several special models:

Model РТА (М10)

M10 is a hybrid heat exchanger that combines the advantages of a collapsible and brazed model at the same time. This model is used for powers up to 150 kW and has found wide application for heating small pools, for heating water for hot water supply, and in cases where a small size of the apparatus is required with maximum efficiency, and untreated water is used for heat exchange, causing contamination of heat exchange surfaces , for the cleaning of which it is necessary to disassemble and mechanically clean the heat exchanger.

Heat exchanger design DW

Double wall - double wall heat exchangers. They are mainly made on the basis of the B16 and B35 models. An important advantage of these models is their high reliability and guaranteed protection against mixing of aggressive media. Due to the double wall, in case of corrosion of the first plate, mixing does not occur, since there is a second plate. At the same time, the medium flows out of the gap between the two plates, signaling a leak.

Heat exchanger version HP

High Pressure - SWEP heat exchanger for high pressure media, over 60 bar. These models have a special reinforcement frame with tightening bolts around the perimeter.

Heat exchanger version AS

All-Stainless - the heat exchanger is completely made of stainless steel. The scope of such a device is production lines made of stainless steel, as well as processes where contact of the medium with copper solder is unacceptable, for example, if ammonia, which destroys copper, is used as one of the heat carriers.

Heat exchanger version True-dual

Heat exchangers SVEP DV, DP, DF series are evaporators with two independent circuits for freon and one circuit for the cooling medium. The design feature of these heat exchangers allows them to be used in refrigeration systems with two compressors, ensuring high reliability.

Heat exchangers ADWIS series

ADWIS air dryers are combined heat exchangers consisting of a cooling heat exchanger, a moisture separator and a regeneration section. They are made on the basis of heat exchangers of the size range 35, 60, 80, 100, depending on the required power. Initially humid air passes through the regeneration section with dehumidified air and enters the cooling section. After cooling, the air enters the moisture trap and dry air exits through the regeneration section.

Heat exchanger SWEP T-REG

Unique model from SWEP company. An integrated solution that includes an electric heater, heat exchanger and connecting piping. It is widely used in systems requiring fast and accurate temperature control to ensure high productivity and quality (for example, in the plastics industry). The T-REG, integrated into a single unit, is equipped with: an electric heater that provides the plastic paste with the desired viscosity, a single-phase water-to-water heat exchanger that cools the mold to cure the plastic, and all the necessary piping between the two sections. The result is a compact, easy-to-install solution that provides extremely accurate temperature control.

OPEKS Energosystems maintains a wide range of different models of SWEP brazed heat exchangers in stock. But even if you need a model that is not presented in our warehouse, we provide an acceptable delivery time up to 1-2 weeks, subject to the availability of this model in the manufacturer's warehouse in Europe.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

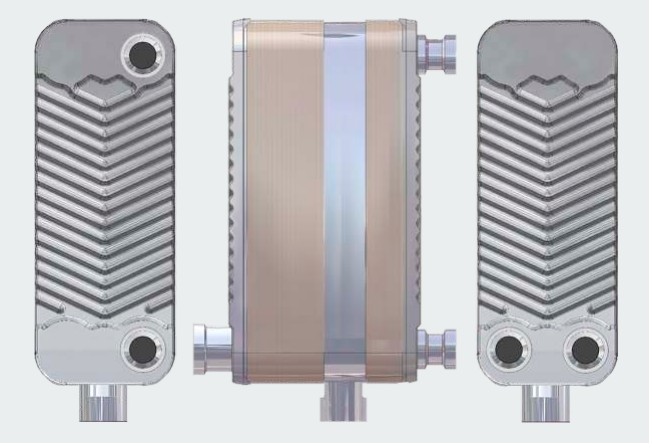

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442