Heating of circulating water with steam is a very common technical problem. The classic way to solve it is to use a plate heat exchanger.

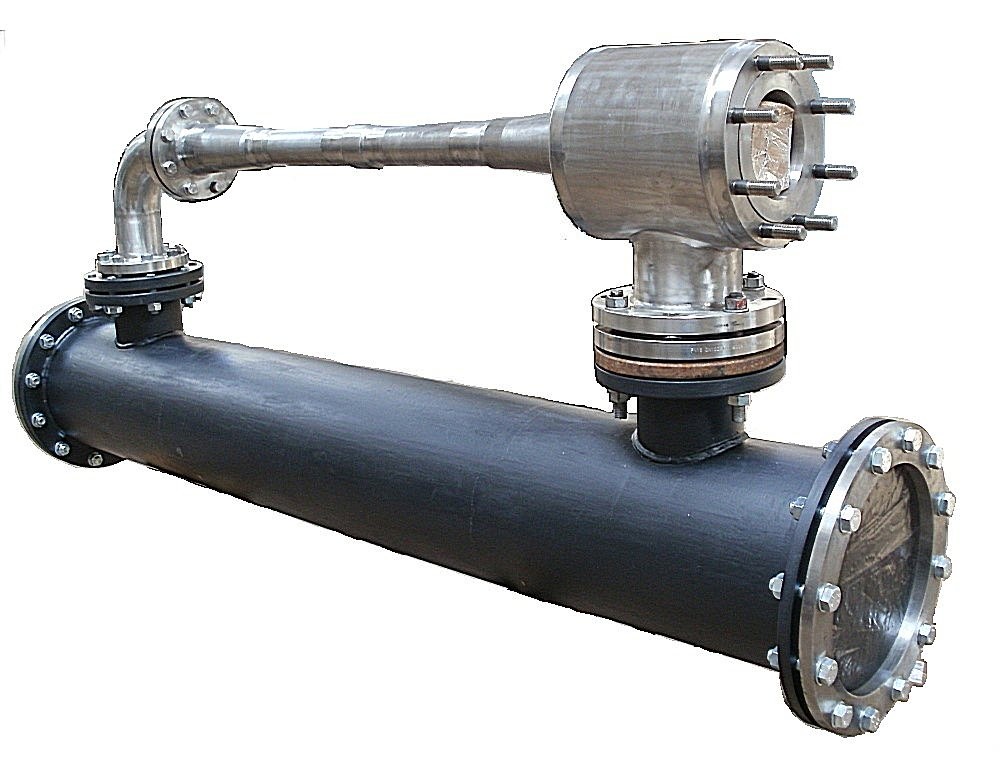

However, there are times when the use of a heat exchanger is economically and technologically impractical. An alternative solution is the use of a steam jet heater, in which the injection process is carried out, which consists in transferring the kinetic and thermal energy of the steam flow to the water flow by their direct contact (mixing flows). With the help of this device, our company successfully solved a specific task - to heat the water flow from 30C to 45C, with a flow rate of 750 t / h. For this, a design was implemented in which only a certain part of the water flow passed through the ejector , heating up to a high temperature of 80-90C.

After the ejector, this stream is again connected to the main cold stream, as a result of mixing the streams, a predetermined temperature of 45C was reached. As a result, the customer received a steam-jet circulating water heater several times cheaper than a heat exchanger, not susceptible to clogging, not containing consumables (seals, etc.), which does not require highly qualified service personnel. The disadvantages still include the lack of condensate return and an increase in the volume of circulating water by the amount of steam consumption.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442