Today, the energy community is witnessing a trend towards a clear increase in interest in alternative energy sources and installations that operate in these systems. In developed countries, such as the USA, Japan, Denmark, Germany, etc., you will no longer be surprised by the presence of a solar collector or a heat pump (HP) in homes. Such a huge popularity of such equipment, in addition to its economic benefits, is due to high social awareness in the energy sector, as well as the financial security of the population. Unfortunately, the Ukrainian consumer is only now beginning to get acquainted with the advantages of alternative energy sources. At the moment, the main problem on the way to the introduction of such systems on the territory of Ukraine is their relatively high cost per unit of supplied heat.

This article was created by the specialists of NPP OPEKS Energosystems LLC for distribution companies, heat pump manufacturers or organizations that are interested in this topic. Ultimately, the information provided should increase the technical awareness of people in the operation and application of heat pumps. Let's take a look at various HP configurations and the possibilities of effective application of our heat exchange equipment (THERMAKS, SWEP, OPEKS) in these systems.

As you know, a heat pump basically consists of an evaporator, a compressor, a condenser and a choke. We always recommend using brazed heat exchangers of the Swedish company SWEP as heat exchangers in which processes with a phase change take place, of which OPEKS Energosystems has been an official distributor since 1999. SWEP has even specially developed models for use in heat pumps (Heat Pump) with brazed - universal connections, which during the heat exchange process provide minimal hydraulic resistance. Since in HP the lower source is often a low potential (low temperature), it is very important to extract heat from it as efficiently as possible and transfer it to the working fluid - freon. Having a low phase transition temperature of ~ 4..5 0 С at atmospheric pressure, freon begins to evaporate. After that, in order to increase the energy potential, the steam is supplied to the compressor, where the process of increasing the pressure and temperature takes place by compressing it. Hot steam enters the next heat exchanger, where it condenses and transfers its energy to the heat carrier circulating in the heating system. Few people know, but from the point of view of thermodynamic efficiency, it is better to use a heat pump with low-energy heating devices (underfloor heating).

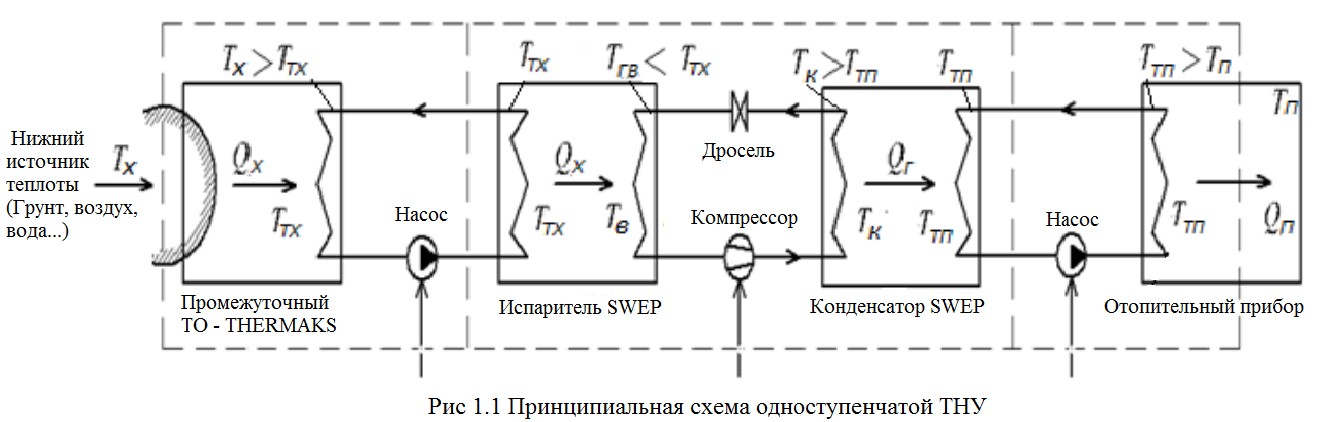

A huge amount of attention is now being paid to improving the efficiency of enterprises through the disposal of industrial waste, waste water and ventilation emissions. These flows can be used as a lower heat source for a heat pump unit (HPU). If an enterprise or a house has relatively clean wastewater that is simply discharged into the environment, then using the THERMAKS plate heat exchanger of the PTA models, we can take energy and transfer it to an intermediate heat carrier (propylene solution, ethylene glycol, water), which will then enter evaporator. Another example is based on the presence of warm air emissions in an enterprise with heavy loads on the ventilation system. A significant amount of air energy can be taken by using the OPEKS-3 heater, inside the tubes of which a secondary heat carrier can move. A schematic diagram of the HPU operation with heat fluxes is shown in Figure 1.1. To simplify the scheme, heat losses to the environment can be neglected.

As seen in Figure 1.1. for the selection of heat exchange equipment (THERMAKS, SWEP, OPEKS) that works in heat pump installations of HPU, you need to operate with the following parameters:

- Lower source temperature T X ;

- The amount of heat that is taken from the lower source and transferred to the intermediate heat carrier, heating it to the temperature T TX ;

- Freon evaporation temperature T B and the amount of heat Q X , which is supplied to it from the intermediate heat carrier;

- Freon condensation temperature T K ;

- Heating system load Q Г ;

The information provided is for informational purposes only in order to popularize alternative energy sources for industrial and domestic use. As well as an overview of various solutions in the field of heat exchange that OPEKS Energosystems is ready to develop in a short time. Send tasks to the specialists of OPEKS Energosystems!

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442