An individual heating station (IHP) is an important link between the heat source and the consumer. ITP consists of complexes of automatic devices, heat exchangers, pumps, shut-off and control valves and heat energy metering units, usually located in the basement or on the technical floor.

The OPEKS Energosystems company has undertaken to carry out a complex of works on the reconstruction of the existing heat point of ZhKK "Vympel", with the registration of a new heat metering unit.

The main task that was set to our company was to reduce the payment for consumed heat, free the existing premises for the economic purposes of condominiums, move the heating point to the free premises provided, do everything efficiently and at the same time, keep within the existing budget of the customer, which was made.

The complex of reconstruction works included:

- General construction work on the arrangement of the premises for the installation of a modular block with weather-dependent regulation of the building's heating system.

- Replacement of the existing heat metering unit with a new one. Since before the reconstruction the heating system operated through the elevator unit, according to the design decision, the elevator unit was left as a backup. During the operation of the heating system, the elevator unit is blocked by ball valves at the inlet and outlet. The connection of the supply and return pipelines of the modular unit with weather-dependent regulation is made up to the elevator unit, thus the renewed heating system works independently of it.

- Making a drainage pit and providing automated drainage using a drainage pump.

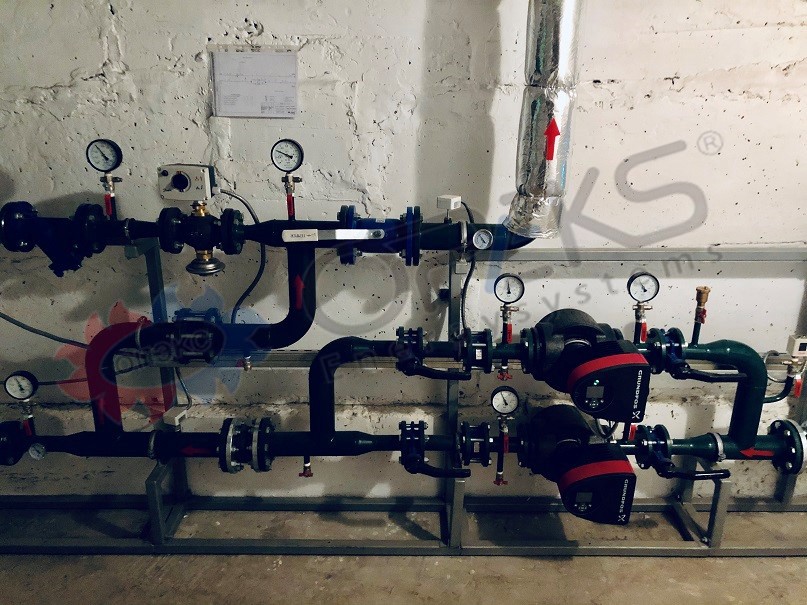

- Development and manufacture of an automated modular heating system unit OPEKS MTP-OZ-523 at the production of OPEKS Energosystems.

- Work on the installation of a new modular block of the OPEKS MTP-OZ-523 heating system, laying pipelines to the tie-in points (welding work was carried out by professional argon welding), work on transferring existing communications with polypropylene pipelines, arranging a drainage pit and connecting to a gravity drainage system of a residential building, insulation mineral wool pipelines.

- After the completion of the installation work, work was carried out to connect the control cabinet, automation equipment, connect the lighting and power supply of the ITP.

- Commissioning work, which included flushing, hydraulic tests, setting up the heat energy meter and complex adjustment of the automated operation of the ITP system. Also, pipelines were marked and other work was done to prepare the ITP for registration of a commercial heat metering unit.

- Upon completion of the commissioning, a number of measures were taken to sign the Act of acceptance of the heating metering unit in state bodies, after the signing of this document, the heat energy meter for this individual heating point was registered.

Thus, the specialists of OPEKS Energosystems have successfully completed all the necessary work on the turnkey reconstruction of the ITP.

Photos of the premises before reconstruction:

Photos of the premises after reconstruction:

OPEKS Energosystems has all the necessary resources to carry out a full range of works on the modernization and reconstruction of heating units (ITP).

Working with us you will receive:

- significant savings on payment for heat energy, depending on the existing system, from 10 to 50%, since we use the most modern automated weather-dependent systems for regulating the temperature of the coolant, high-quality equipment and metering devices;

- comfortable room temperature, depending on the external ambient temperature and really hot water during the peak water withdrawal period:

- timely warranty and post-warranty service of all equipment installed by us.

Why OPEKS Energosystems?

- We have been working on the market for over 20 years and have the necessary experience and resources;

- You do not need to overpay, since we are the official distributor of all well-known manufacturers of heating station components, such as THERMAKS, DANFOSS, BELIMO, ESBE, WILO, GRUNDFOSS and others;

- we ourselves produce plate heat exchangers THERMAKS, using Swedish components, we produce block heating units OPEKS MTP, pumping stations HYDROMAKS, control cabinets and other equipment at our own modern production in the Boryspil region;

- we carry out service maintenance of all equipment of heat points;

- we will try to keep within your budget and will do the entire volume of work as efficiently as possible;

- You can always visit our company, office and production and see with your own eyes how we work.

We call on the owners of residential and administrative buildings, condominiums, housing cooperatives, UBB to cooperate with us!

Photo: THERMAKS heat exchangers of our own production against the background of the OPEKS plant.

Photo: The process of collecting an individual heating point in production.

Photo: Ready individual heating station OPEKS MTP in modular design at the production of OPEKS Energosystems before being sent for further installation.

Photo: The final stage of installation of OPEKS heating units in a new residential building.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442