OPEKS ENERGOSYSTEMA supplies special graphite heat exchangers for heat exchange processes with aggressive media, such as hydrochloric, sulfuric, nitric acids, and other inorganic and organic acids. Depending on the tasks set, plate, tubular, block heat exchangers can be used. So, for example, in the production of textile viscose, heating of a 20% sulfuric acid solution up to 60 C is used, a graphite plate heat exchanger can easily cope with this task. In the production of sulfurous salts, tubular graphite heat exchangers with low hydraulic resistance and a wide flow area have proven themselves well due to the use of larger diameter graphite pipes. The service life of graphite heat exchangers, depending on the technological process, ranges from 5 to 15 years, while the heat exchangers with lead surfaces used in the past had a service life of up to 1 year.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Float steam trap Yoshitake TSF-8-5 DN15

Float steam trap Yoshitake TSF-8-5 DN15

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Float steam trap Yoshitake TSF-8-5 DN25

Float steam trap Yoshitake TSF-8-5 DN25

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Float steam trap Yoshitake TSF-10F-10 DN15

Float steam trap Yoshitake TSF-10F-10 DN15

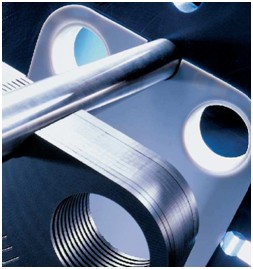

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442