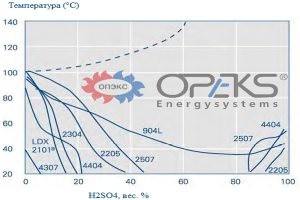

The use in industry of media other than the coolant - water, puts forward new, increased requirements for heat exchange equipment. For example, for sulfuric acid, depending on the concentration, it may be unacceptable to use stainless steel and NBR or EPDM seals, but it is necessary to use heat exchange surfaces made of steels such as Hastelloy, 254SMO with Viton gaskets. In many cases, graphite heat exchangers are the only solution. Correctly selected material of the heat exchanger will allow you to work with acid of any concentration for a long time and reliably.

OPEKS ENERGOSYSTEMY has extensive experience in the selection and manufacture of plate heat exchangers THERMAKS of the PTA (GX), PTA (GL), PTA (GC) series for various technological processes. A wide range of manufactured heat exchange equipment allows you to find the most effective solution for various heat exchange problems.

Our heat exchangers have the following main characteristics:

- Working temperature from -20 ° C to + 180 ° C

- Working pressures from 6 to 25 bar

- Connection sizes DN 25 to DN 500

- Unit power from 5 kW to 30 MW.

Safety valve LESER 441/442 DN20/32

Safety valve LESER 441/442 DN20/32

Safety valve LESER 441/442 DN25/40

Safety valve LESER 441/442 DN25/40

Safety valve LESER 441/442 DN32/50

Safety valve LESER 441/442 DN32/50

Safety valve LESER 441/442 DN40/65

Safety valve LESER 441/442 DN40/65

Safety valve LESER 441/442 DN50/80

Safety valve LESER 441/442 DN50/80

Safety valve LESER 441/442 DN65/100

Safety valve LESER 441/442 DN65/100

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Float steam trap Yoshitake TSF-8-5 DN15

Float steam trap Yoshitake TSF-8-5 DN15

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Float steam trap Yoshitake TSF-8-5 DN25

Float steam trap Yoshitake TSF-8-5 DN25

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Float steam trap Yoshitake TSF-10F-10 DN15

Float steam trap Yoshitake TSF-10F-10 DN15

Shell and tube coolers

Shell and tube coolers