| Parameter name | Meaning |

| Maximum design condensate temperature, ºC | up to 180, others on request |

| Maximum working pressure, MPa | up to 0.8, others on request |

| Consumption, kg / h | 100 ... 30000 |

| Connection diameter, DN | 25 ... 250 |

| Receiver volume, l | 50 ... 500 |

| Control environment | Steam, air |

| Pressure regulator of direct action on the pipeline of the control medium | option |

| Material of pipelines and / or containers | Carbon steel, stainless steel |

| Overall dimensions (roughly, depend on the design load) LxHxW, mm | (1000 ... 2000) x (1000 ... 2000) x (500 ... 1000) |

| Non-standard execution | Possible upon request |

Condensate pumping station with mechanical pumps is designed to return hot condensate (90 ° C and above) back to the condensate tract to feed steam boilers. Mechanical pumps operate in a cyclic mode, therefore, they do not imply large storage tanks. The unit is used in the case when the condensate's own pressure is not enough to reach the boiler room or when it is necessary to separate the consumer and the condensate drain.

The condensate pumping station is made on the basis of mechanical pumps of the Japanese company YOSHITAKE, is completely autonomous and does not require an electric power supply. It is possible to use condensate pumps from other manufacturers.

An example of designation of a condensate collection and pumping station produced by OPEX ENERGOSYSTEM:

МТП-НС№-М№-V TU 29.2-31777170-001: 2006,

where

- НС - the purpose of the unit is a make-up pumping station with an indication of the number of pumps;

- М№ - model number of installed pumps;

- V - receiver volume - condensate collection tank.

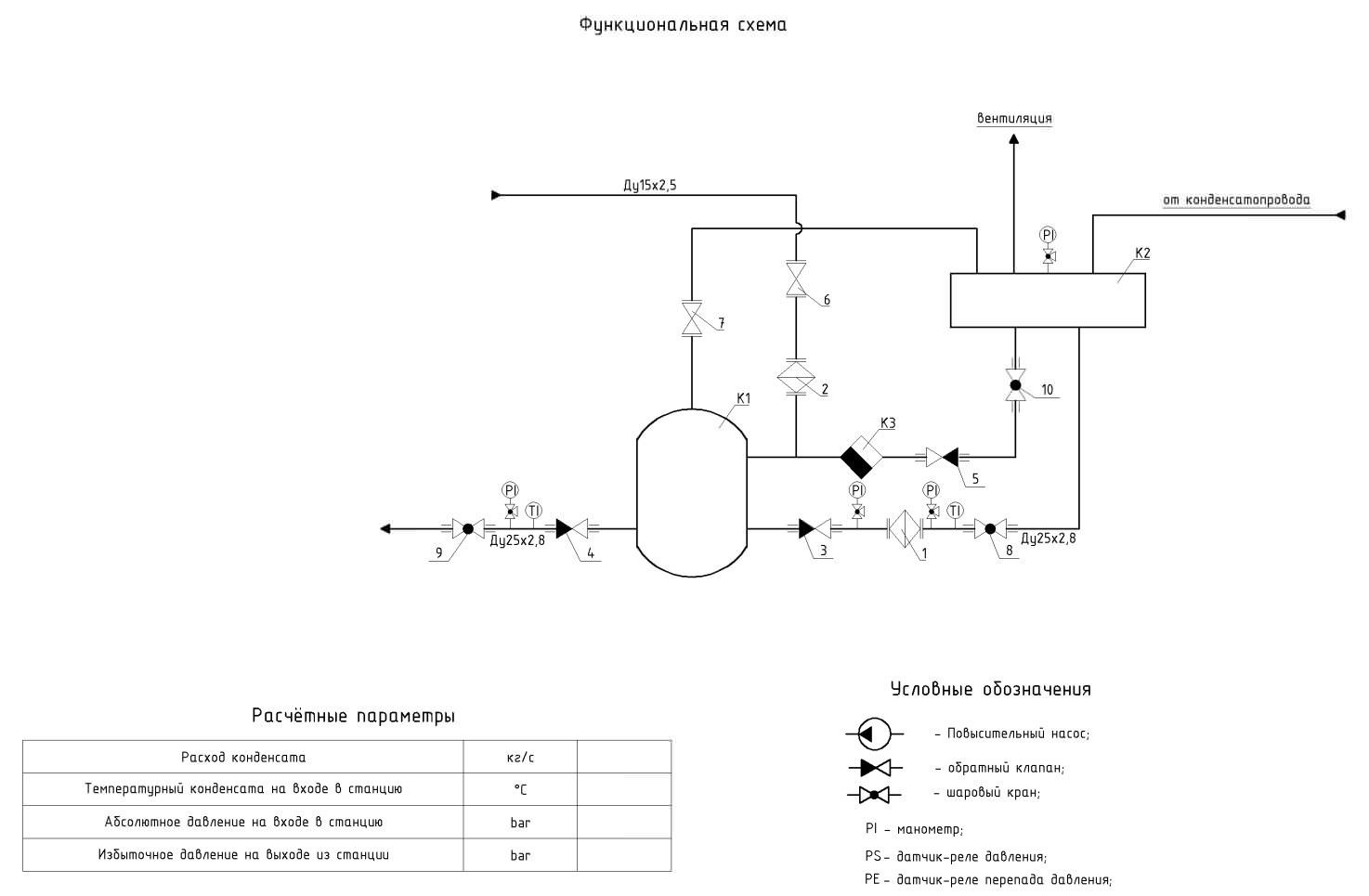

The condensate pumping unit consists of the following main elements:

- 1. Receiver - tank for collecting condensate

- 2. Mechanical condensate pump (from 1 unit)

- 3. Frame

- 4. Condensate drain

- 5. Shut-off valves

- 6. Pressure gauges (optional)

- 7. Thermometers (optional)

The condensate receiver is equipped with condensate inlet pipes, a pressure header, and a ventilation pipe.

The condensate collection tank is available in either carbon steel or stainless steel, depending on customer preference.

The selection of mechanical condensate pumps for each installation is carried out individually, depending on the required head and capacity of the condensate system.

The advantages of using a condensate pumping unit are as follows:

- 1. Development of the installation is carried out on the basis of technical specifications

- 2. Each module is developed in accordance with the requirements and wishes of the customer

- 3. Complete autonomy, no electricity connection required.

- 4. Fast and easy on-site installation

- 5. Compact design

- 6. Factory production using modern technologies and equipment from the best manufacturers.

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard