| Parameter name | Meaning | |||

| Model | OB-2 | OB-2G | ||

| Application | Heat | Steam, hot water | ||

| Heat. Wednesday | Cold and hot water, oil, other non-hazardous liquids | |||

| Max. pressure | Frame | 15A-40A: 0.7 MPa (1.0 MPa) 50A: 0.5 MPa (0.7 MPa) 65A: 0.5 MPa (0.7 MPa) 80A: 0.4 MPa (0.5 MPa) 100A: 0.4 MPa 125A: 0.2 MPa (0.35 MPa for OB-2) 150A: 0.2MPa | ||

| Thermal balloon | 1.0 MPa | |||

| Max. temperature | 180 ° C | |||

| Setting range temp. | For liquid | 40-120 ° C | 15-100 ° C | |

| For air | 40-120 ° C | 15-100 ° C | ||

| Pace. surrounded Wednesday | Set temperature -10 ° C or less | Set temperature +30 ° C or less | ||

| Material | Frame | Cast iron | ||

| Valve, valve seat | Phosphor bronze (stainless steel) | |||

| Valve stem | Stainless steel | |||

| Bellows | Phosphor bronze | |||

| Thermal balloon | Stainless steel | |||

| Std. capillary length | 15A-80A: 2m 100A-150A: 3m | |||

| Compound | Flange connection JIS 10K FF | |||

- If the ambient temperature is above the set temperature or below 40 ° C, use OB-2G (with external pressure bellows).

- For applications with pressures over 0.5 MPa, it is recommended to use a model with stainless steel control parts.

- Available with capillary tube up to 5 m.

- Available with maximum temperature. (Valve mechanism and seat materials and bellows are different from the standard model.)

- Available with sleeve (SUS304 or PTFE cap) for fluid.

Temperature setting range

OB-2

| Setting range temp. (° C) | Withstanding temperature (° C) | |

| For liquid | For air | |

| 40-60 | 40-60 | 70 |

| 50-70 | 50-70 | 80 |

| 60-80 | 60-80 | 90 |

| 80-100 | 80-100 | 110 |

| 100-120 | 100-120 | 130 |

- The term withstand temperature refers to the maximum temperature at which the bellows can withstand internal pressure.

- Options with a temperature control range of 30 ° C are available (only OB-2).

OB-2G

| Setting range temp. (° C) | Withstanding temperature (° C) | |

| For liquid | For air | |

| 15-35 | 15-35 | 50 |

| 20-40 | 20-40 | 50 |

| 35-55 | 35-55 | 70 |

| 40-60 | 40-60 | 90 |

| 50-70 | 50-70 | 100 |

| 60-80 | 60-80 | 110 |

| 70-90 | 70-90 | 120 |

| 80-100 | 80-100 | 130 |

The term withstand temperature refers to the maximum temperature at which the bellows can withstand internal pressure.

- Temperature adjustment is carried out using a knob without the need for additional tools.

- The double valve design allows higher flow rates than a single valve.

- Exceptional precision due to special stem packing which influences the opening and closing of the valve.

- The OB-2G model provides excellent thermal stability thanks to the external pressure bellows.

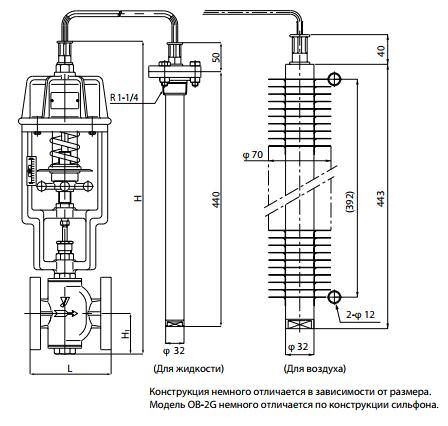

| Nom. the size | L | H 1 | H | The weight |

| 15A | 126 | 60 | 520 | 15 |

| 20A | 130 | 60 | 520 | 16 |

| 25A | 140 | 70 | 540 | eighteen |

| 32A | 150 | 75 | 550 | 21 |

| 40A | 160 | 75 | 550 | 23 |

| 50A | 180 | 110 | 620 | 29 |

| 65A | 215 | 125 | 650 | 38 |

| 80A | 260 | 135 | 700 | 48 |

| 100A | 300 | 160 | 750 | 58 |

| 125A | 360 | 190 | 810 | 76 |

| 150A | 382 | 220 | 980 | 125 |

The OB-2G model is available in sizes up to 125A.

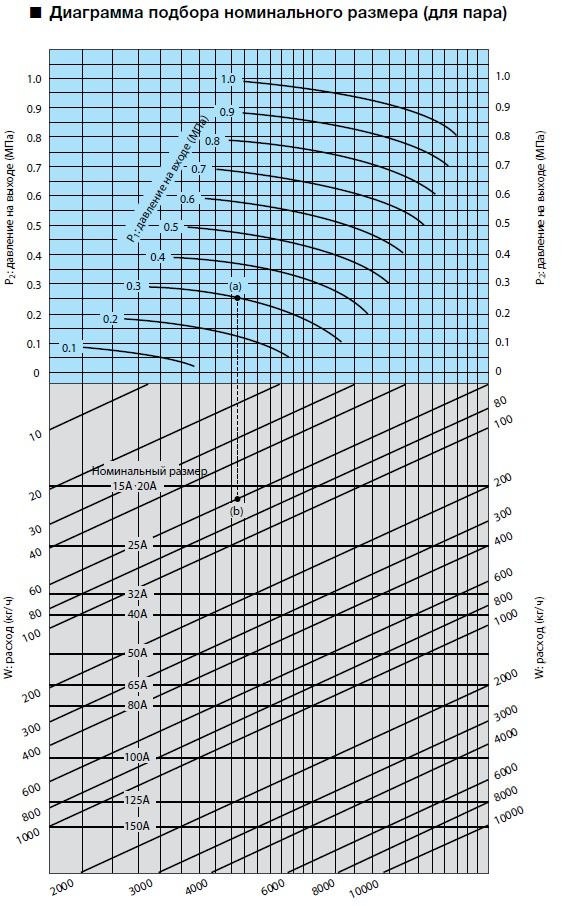

How to use a chart

When selecting the nominal size of the temperature controller at inlet pressure (P1), outlet pressure (P2) and steam flow rates of 0.3 MPa, 0.25 MPa and 60 kg / h, respectively, first find the point of intersection (a) of the pressure lines on inlet 0.3 MPa and outlet pressure 0.25 MPa. From this point (a) draw a line down to the intersection with the line corresponding to the flow rate of 60 kg / h - the point of intersection (b). Since this intersection point (b) lies between the nominal sizes 15A or 20A and 25A, select the larger one, 25A.

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard