| Parameter name | Meaning |

| The pumped-over medium | Water |

| Pump manufacturer | WILO, GRUNDFOS, others |

| Network connection, V | 3x380 V, 50 Hz |

| Design pressure, MPa | 1.6 |

| Design temperature, ºC | 50 (standard), 70 and above (on request) |

| Total number of pumps, pcs | 2 to 4 |

| Number of standby pumps, pcs | 1 (standard) |

| Carrying frame material | painted steel (standard), st. steel |

| Carrying frame type | reinforced |

| Suction and Discharge Manifold Material | painted steel (standard) |

| Pressure sensors 4-20mA | Danfoss |

| Controllers in the control cabinet | Segnetics (standard), Siemens, others |

| Automatic machines, starters, relays | ETI (standard), ABB, Moeller, others |

| Dry run protection | option |

| Motor overload protection | there is |

| Expansion tank | option |

Fire pumping stations are designed to instantly supply the maximum possible calculated amount of water for the purpose of extinguishing a fire in residential, office, warehouse, industrial, agricultural and other premises. Fire extinguishing installations are subject to increased reliability requirements.

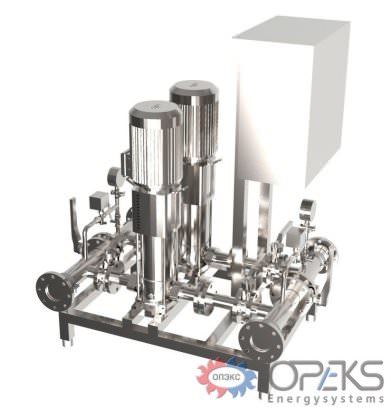

In the production of pumping stations for fire extinguishing, OPEKS ENERGYSYSTEM uses all equipment of a high quality standard. The set of the installation includes one or two main working pumps WILO or Grundfos and one standby pump of the same standard size, a fire control cabinet (PSHU), shut-off and switching valves, and a pressure sensor. All equipment is compactly mounted on a supporting frame. The fire extinguishing station is automatically switched on after a signal from the fire alarm sensor, or after manually pressing the "Fire" button.

The pump control circuit is implemented according to the "on / off" principle. An output signal can be provided in the cabinet to control the opening of a bypass valve that allows water to flow past the water meter to increase higher capacity. For fire extinguishing installations, frequency regulation by pumps is not used, since, in the event of a fire, the maximum performance of all working pumps is required.

Each fire extinguishing station is completed with a passport and operating instructions.

Characteristics of pressure boosting systems for fire extinguishing systems based on WILO pumps, which are produced at the OPEKS ENERGYSYSTEM plant:

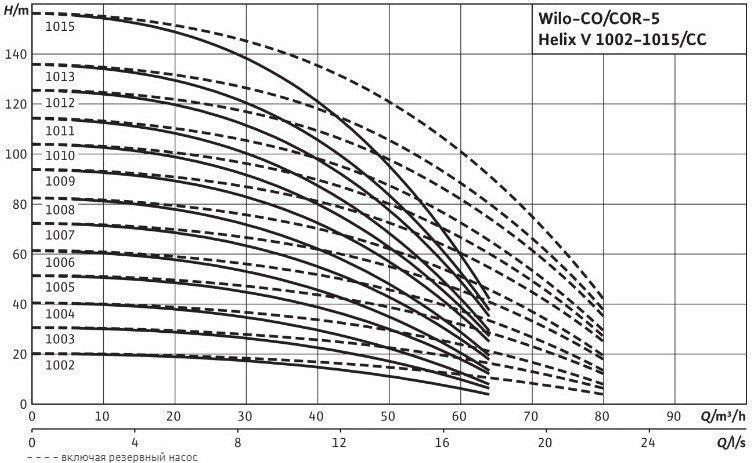

| Pumping station HYDROMAKS HC- (2..5) -Helix / RF based on 2-5 series pumps WILO Helix V, analogue of the installation Wilo-CO / COR-Helix V… / CC  |  |

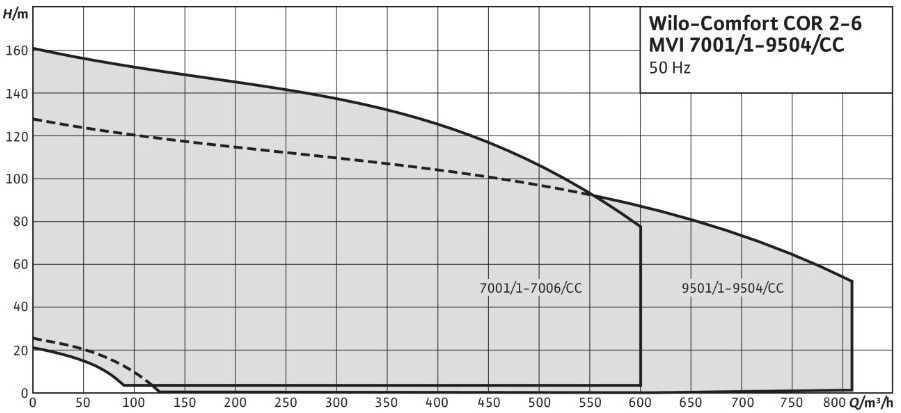

| Pumping station HYDROMAKS HC- (2..6) -MVI / RF based on 2-6 series pumps WILO MVI, analogue of the installation Wilo-Comfort COR ... MVI ... / CC  |  |

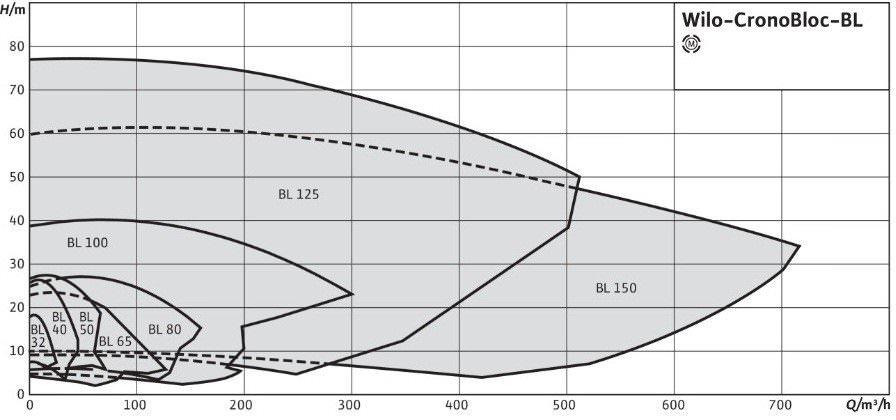

| Pumping station HYDROMAKS HC-2-BL / RF based on the 1st working pump of the WILO BL series (other number of pumps on request) installation analog Wilo-Cronobloc-BL  |  |

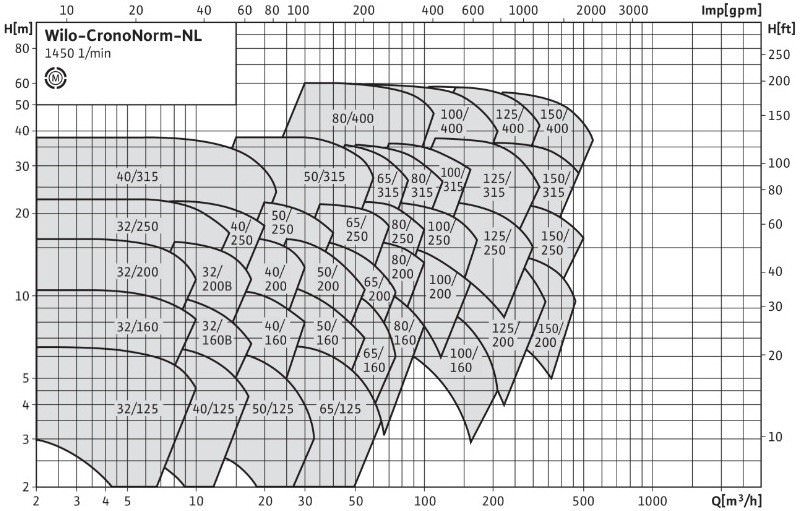

| Pumping station HYDROMAKS HC-2-NL / RF based on the 1st working pump WILO NL series, 2900 rpm (other number of pumps on request) installation analog Wilo-CronoNorm-NL  |  |

| Pumping station HYDROMAKS HC-2-NL / RF based on the 1st working pump WILO NL series, 2900 rpm (other number of pumps on request) installation analog Wilo-CronoNorm-NL  |  |

Characteristics of pressure boosting systems for fire extinguishing systems based on Grundfos pumps, which are produced at the OPEKS ENERGYSYSTEM plant:

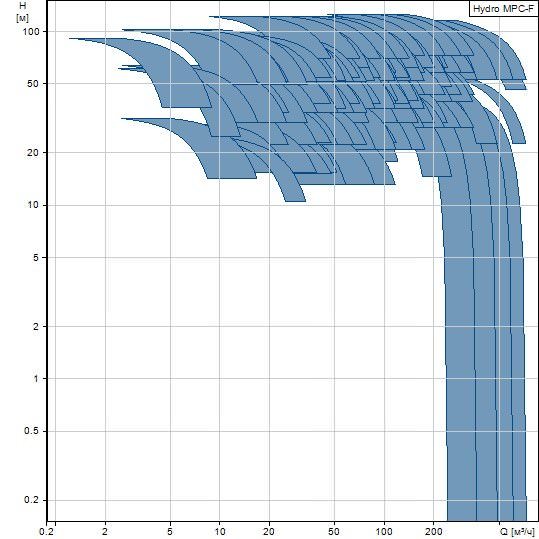

| Pumping station HYDROMAKS HC- (2..5) -CR / RPN based on 2-5 pumps of the GRUNDFOS CR series, analogue of the unit Grundfos-Hydro MX ... CR ...  |  |

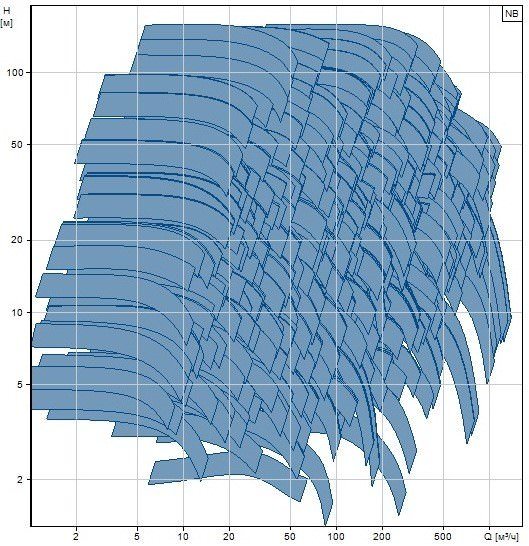

| Pumping station HYDROMAKS HC-2-NB / RPN based on the 1st working pump of the GRUNDFOS NB series (other number of pumps on request) installation analog Grundfos-Hydro MX ... NB ...  |  |

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard