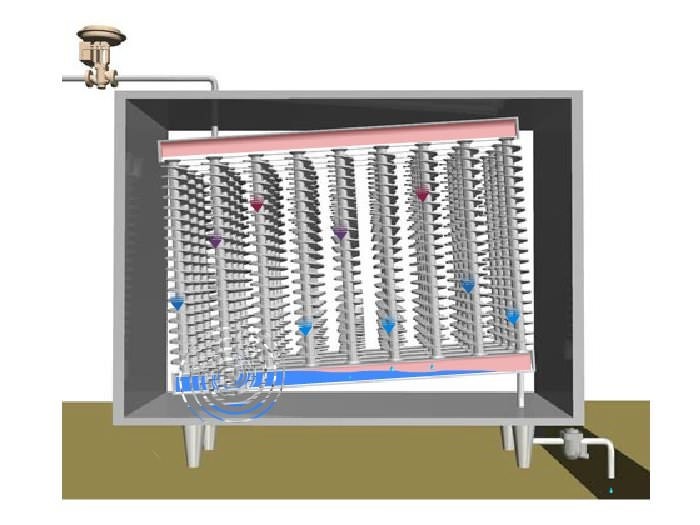

Water hammer inside heat exchange equipment, like water hammer in steam distribution lines, is often the result of accumulation and stagnation of condensate. For example, consider the operation of a shell-and-tube heat exchanger . When the heat load on the equipment decreases (due to a decrease in the amount of heated product or an increase in its temperature), by reducing the steam supply, the pressure difference between the inlet and outlet of the steam trap decreases and condensate begins to accumulate inside the heat exchanger. This phenomenon is known as "condensation stagnation". When steam is reintroduced into a flooded heat exchanger, it instantly condenses and a water hammer is formed. In most cases, the force of a water hammer in a heat exchanger is less than in a steam line, but its prolonged effect leads to "fatigue" of the metal, followed by its destruction and failure of the heat exchanger.

Deformation of the tube bundle under the influence of water hammer

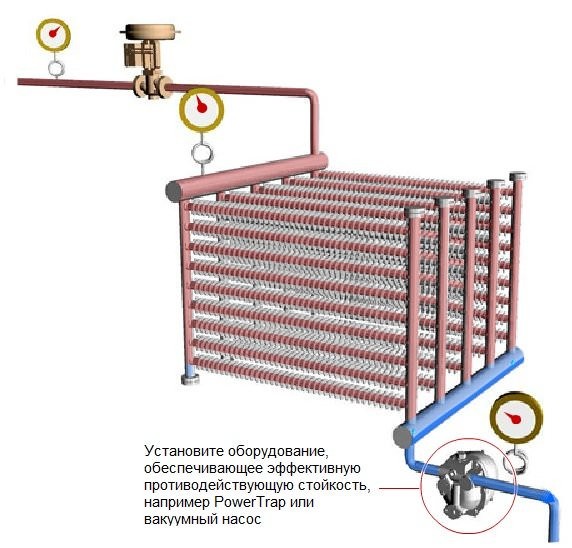

The main reasons for stagnant condensate in heat exchangers:

Incorrect hardware installation

High back pressure in the condensate line

To prevent flooding of heat exchangers, it is most effective to use Yoshitake pumping steam traps.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442