The phenomenon of stagnation of condensate can be described as follows: while regulating the supply of steam to the heat exchanger , in order to change its heat load, the pressure in it changes. At a certain load level, the control valve will reduce the steam pressure to a value equal to or below the back pressure downstream of the steam trap. In this case, the condensate will not be able to overcome the head in the condensate line and will begin to accumulate in the heat exchanger, until it is completely flooded, until the control valve, increasing the heat load, increases the pressure above the back pressure value and displaces the condensate from the heat exchanger. Accordingly, the higher the back pressure value in the condensate line, the larger the load range falls into the operating mode under flooding.

Flooding or stagnation of condensate leads to uneven heating, water hammer, deformation and destruction of the heat exchanger.

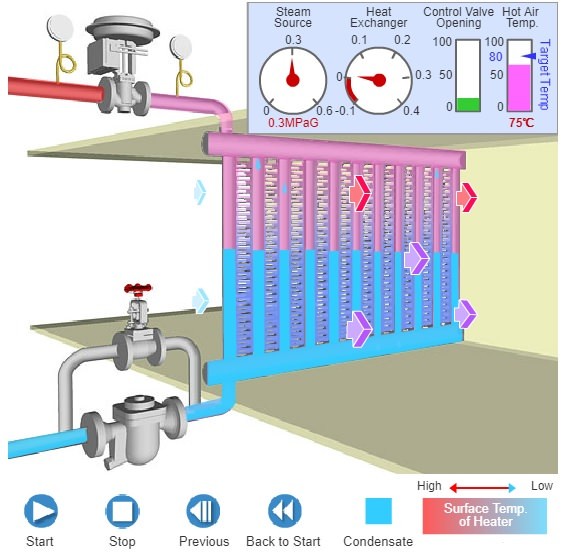

The process of stagnation of condensate is shown in more detail in the animation using the example of a heater.

In the system shown, a steam heater with a steam pressure of 3 bar is used to heat the air to 80 ° C. When starting up the system, to quickly warm up the heat exchanger and reach the set air temperature, the control valve is in the position - 100% open. Accordingly, the pressure in the heat exchanger is equalized with the pressure in the steam line and is set within 3 bar. Further increase in air temperature is limited by closing the valve and reducing the steam supply. Its pressure decreases and the heat exchanger is flooded with condensate. This leads to a decrease in the air temperature, to which the control valve responds by opening and increasing the pressure in the heat exchanger. Condensation is discharged and the air temperature rises. Then the cycle repeats.

Water hammer with stagnant condensate

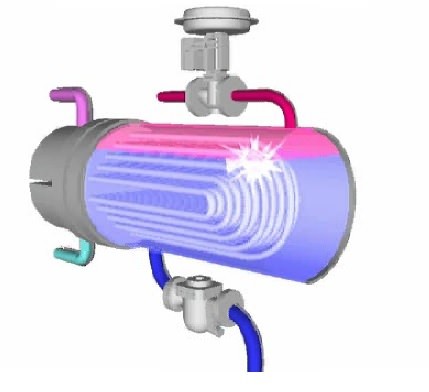

In a flooded heat exchanger, water hammer occurs due to the instantaneous condensation of steam upon contact with condensate. The resulting vacuum leads to a sharp collapse of the liquid medium and the propagation of a shock wave in the condensate. This is fraught with deformation and destruction of the elements of the heat exchanger and its failure.

Defective products

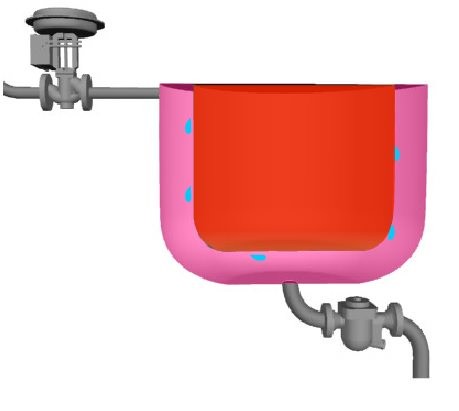

Uneven heating of the product, especially in the food industry, leads to a decrease in quality or product rejection. This can be seen by observing the flooding of the steam jacket of the digester during the heating process.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442