What is steam?

Water vapor is formed when water changes from a liquid to a gaseous state. This is accompanied by the absorption of a significant amount of energy, called latent heat of vaporization. In the opposite process, the condensation process, the same amount of heat is released. This is the main principle of heat transfer with the help of steam, that is, the use of phase transition energy.

There are the following types of steam conditions: wet saturated steam, dry saturated steam and superheated steam.

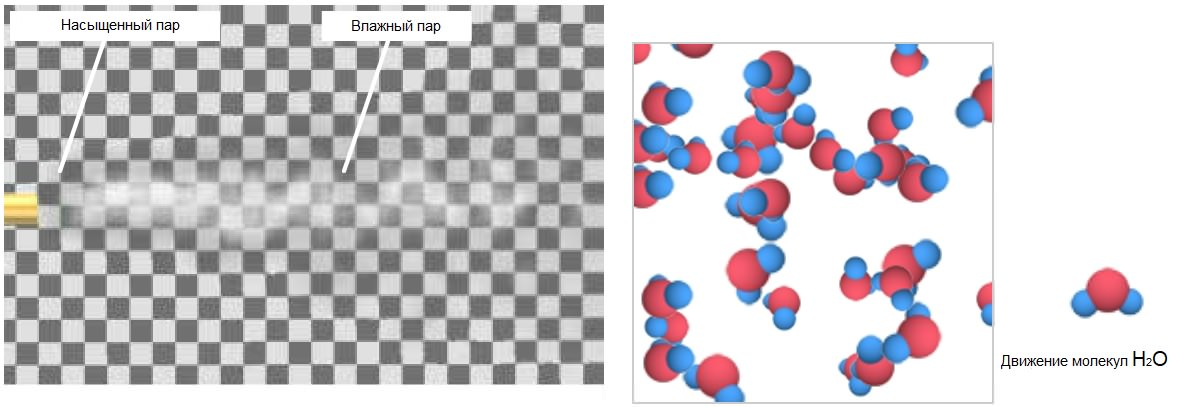

Wet saturated steam

This is the most common form of steam, in which some of the water molecules have given up their energy (latent heat) and condensed, forming tiny water droplets in the form of a fog. The concept of dryness (humidity) of steam characterizes the amount of dropping liquid contained in saturated steam.

In practice, even the best boilers produce steam containing 3% - 5% moisture. Since the generated steam carries with it, some of the water is usually in the form of mist or droplets.

The operation of wet steam increases energy consumption and has several disadvantages. With an increase in the moisture content of saturated steam, its enthalpy (energy efficiency) significantly decreases, pressure losses in the steam pipeline increase, steam pipelines are subject to erosion, and the likelihood of condensate accumulation appears, leading to water hammer and destruction of steam pipelines and equipment.

Therefore, when designing and operating steam-condensate systems, it is necessary to provide for measures for steam drying (installation of cyclone separators, pressure reducing valves of the COS series) and drainage of steam pipelines (installation of condensate pockets), as well as thermal insulation of all sections of steam pipelines and fittings.

Dry saturated steam

The transparent gas, free from moisture, has many properties that make it an excellent controllable heat source.

| Peculiarity | Advantage |

|---|---|

| Fast and uniform heating through latent heat transfer | Improving product quality and productivity br> |

| It is used both in technological processes and in the heating and ventilation systems of the enterprise | Simplifies operation and unifies energy distribution in the enterprise. Reduces the cost of power generating equipment. |

| Temperature can be controlled by pressure | Temperature can be set quickly and accurately |

| High heat transfer coefficient | Less heat transfer surface area required, resulting in reduced footprint and lower initial hardware costs |

| Made from water | Safe, environmentally friendly and inexpensive |

Superheated steam

Superheated steam is formed by further heating wet or saturated steam above its saturation temperature.

In this state, the steam has a higher temperature and lower density than saturated steam at the same pressure. Superheated steam is used mainly in various heat engines such as turbines to improve their efficiency and is not usually used for heat transfer.

| Peculiarity | disadvantages |

|---|---|

| Low heat transfer coefficient | Decreased productivity |

| The need to increase the heat transfer surface area | |

| Variable steam temperature even at constant pressure | System controllability deteriorates |

| Physical heat is used to transfer heat | Temperature extremes can have a negative impact on product quality |

| Temperatures can be extremely high | Significant increase in capital costs for the installation of high-temperature equipment |

For these and other reasons, saturated steam is preferred over superheated steam as a heat transfer medium in heat exchangers and other heat transfer equipment. On the other hand, if superheated steam is considered as a heat source for direct heating, as a high temperature gas, it has an advantage over hot air, especially in anoxic conditions. It is also used in the food industry, for drying and processing food products.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442