| Model | DD-2 | DD-2-8 | DD-3 | DD-3-8 | |

| Application | Steam, air, cold and hot water, nitrogen, carbon dioxide (dry), argon, oil | Air, cold and hot water, nitrogen, carbon dioxide (dry), argon, oil | |||

| Fluid viscosity | Not more than 20 cSt | ||||

| Operating pressure | 0-0.15 MPa | 0-0.8 MPa | 0-0.15 MPa | 0-0.8 MPa | |

| Orifis (mm) | 9.5 | 4.0 | 9.5 | 4.0 | |

| Cv value | 1.7 | 0.55 | 1.7 | 0.55 | |

| Permitted. valve seat leak | 50 ml / min under standard conditions | There is no leakage from the pressure gauge | |||

| Max. temperature | 175 ° C | 100 ° C | |||

| Principle | Normally closed | ||||

| Material | Frame | Cast stainless steel (SCS14A) | |||

| Plunger | Stainless steel | ||||

| Valve plug | Fluoroplast | fluoroelastomer | |||

| Compound | Threaded JIS Rc | ||||

Coil Specifications

| Rated voltage | Change voltage AC100 / 200 V with choice of winding | Change voltage AC110 / 220V with winding selection |

| 50/60 Hz total | ||

| Permissible fluctuations | Rated voltage ± 10% | |

| Rated current | 0.42 / 0.21 A | 0.38 / 0.19 A |

| Starting current | 1.10 / 0.55 A | 1.00 / 0.50 A |

| Insulation class | Insulation class H | |

| Protective structure | Dust-proof and splash-proof | |

| Degree of protection | IP64 (JIS C0920) | |

| Insulation resistance | Not less than 500 MOhm at 500 V | |

| Withstand voltage | 1500 V / min | |

* Available with terminal box.

The solenoid valve is opened and closed by moving a steel element called a plunger under the influence of solenoid electromagnetic forces and is used to control the flow of fluid in pipelines (open-close control).

- Outstanding corrosion resistance thanks to stainless steel main parts and housing.

- Significantly improved corrosion resistance thanks to stainless steel housing and control parts.

- Easy maintenance thanks to PTFE gasket.

- The product complies with the Restriction of Hazardous Substances Directive (RoHS).

- Various installation positions: vertical, horizontal or intermediate.

- Equipped with a coil for ~ 110/220 V at choice and 50/60 Hz.

| Nom. the size | d | L | H | H 1 | The weight |

| 10A | Rc 3/8 | 50 | 85.5 | 12 | 0.66 |

| 15A | Rc 1/2 | 60 | 87.5 | 13 | 0.69 |

| 20A | Rc 3/4 | 65 | 91 | 16.5 | 0.74 |

| Model | ØD (mm) |

| DD-2 | 9.5 |

| DD-3 | |

| DD-2-8 | 4.0 |

| DD-3-8 |

Nominal sizing diagram

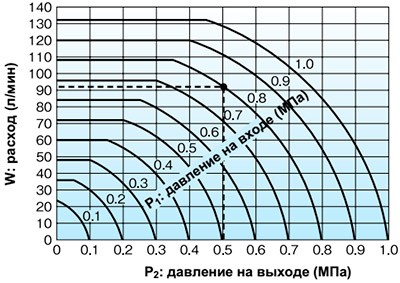

For steam (Cv = 1)

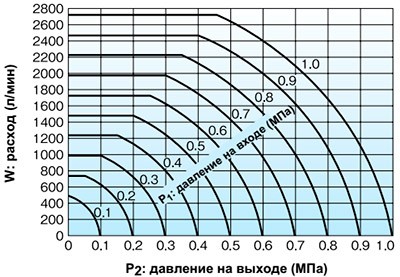

For air (Cv = 1)

How to determine the flow rate (steam, air)

First find the flow rate (W for steam, Q for air), the point of intersection of the pressure lines at inlet P1 and outlet P2. Then multiply the Q or W flow rate by the Cv factor for each model.

Example. • Model: DD-2-8 (Cv value: 0.55)

• Liquid: steam

• Inlet pressure (P1): 0.8 MPa

• Outlet pressure (P2): 0.5 MPa

The flow rate W is 92 kg / h, which corresponds to the intersection point P 1 = 0.8 MPa and P2 = 0.5 MPa, as shown by the dashed line.

Then multiply W = 92 kg / h by a Cv factor of 0.55. Thus: 92 kg / h x 0.55 = 50.6 kg / h

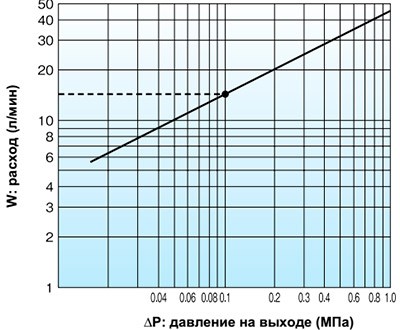

For water (Cv = 1)

How to determine the flow rate (water)

First find the differential pressure ∆P, then find the flow rate V using the diagram above. Then multiply the flow rate V by the Cv factor for each model.

Example. • Model: DD-3 (Cv value: 1.7)

• Inlet pressure (P1): 0.15 MPa

• Outlet pressure (P2): 0.05 MPa

Differential pressure: ∆P = P1 - P2 = 0.1 MPa. Then find the flow rate V = 14 l / min shown by the dotted line in the diagram. Then multiply V = 14 L / min by a Cv factor of 1.7. So: 14 l / min x 1.7 = 23.8 l / min

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard