High throughput, since the devices can be connected to modular units.

| Parameter name | Meaning |

|---|---|

| Operating pressure | up to 100 bar |

| Temperature range | -195 ° C - + 900 ° C |

| Accessions | DN10 - DN800, flanges, weld-on, thread |

| Material | stainless steel AISI 304, AISI 316, titanium, others |

Welded shell-and-plate heat exchangers from OPEKS ENERGYSYSTEM

The welded shell and plate heat exchanger is designed for use with media pressures of 100 bar or more, operating temperatures from -200 to 900 ° C. Structurally, the heat exchanger is a package of round or oval plates, the plates are welded together into cassettes, which are also welded together in a special way, providing resistance to temperature deformations.

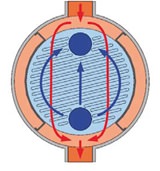

The plate pack, equipped with flow distributors along the entire length of the pack, is installed in a cylindrical casing. One medium circulates in the channel, inside the platinum package, the other medium washes the plate package from the outside.

The inner channel is connected to the inlet and outlet pipes welded to one of the plates (or both at once), which covers the ends of the cylindrical casing. The branch pipes connecting the channel washing the plate pack are welded to the side of the casing. So, for example, steam coolant is supplied to the upper part of the housing through a branch pipe with a diameter that can vary inclusively up to DN800, steam condenses on the surface of the plate pack, washing the inter-plate space and transferring heat to the medium circulating inside the plate pack.

Structurally, the heat exchanger can be made with a collapsible casing, in which the dismantling of the end plate allows the plate pack to be removed for inspection and mechanical cleaning. There are options for manufacturing a heat exchanger when the channel between the plates has 2 nozzles on both sides of the casing. The number of nozzles on the casing side can also vary.

Application examples:

Fully welded steam

condenser type SPW-75,

stainless steel plate package steel AISI316,

body carbon steel

Ammonia evaporator type

SPW-55 with separator

for a refrigeration machine,

stainless steel plate package

steel AISI304 housing

carbon steel

Welded heat exchanger type

SPW-75, completely made of st.

steel AISI316,

collapsible body

with removable plate pack

Two fully welded evaporators

SPW-55 for R507 freon together

with separator, for climatic

installation plate package stainless.

AISI316 steel, carbon steel body

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard