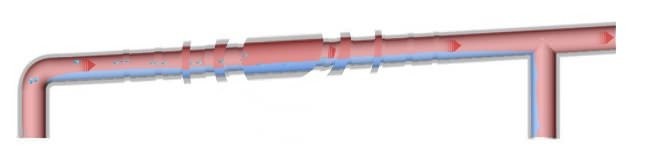

Water hammer in steam distribution lines usually occurs during system start-up and warm-up. Therefore, this process must be carried out methodically, sequentially heating individual sections of the steam pipeline, using drain valves, bypass lines for heating and excluding sudden opening and closing of valves. In addition, steam lines should be provided for steam dehumidification using cyclone separators and condensate drainage by installing condensate pockets with condensate traps. An important condition for effective drainage is to ensure the correct slope of the pipelines, otherwise the condensate will not be able to be efficiently discharged and will accumulate, subsequently forming water hammer.

The slope should be in the direction of steam movement

ANTI-DIFFUSION LEADS TO A WATER SHOCK

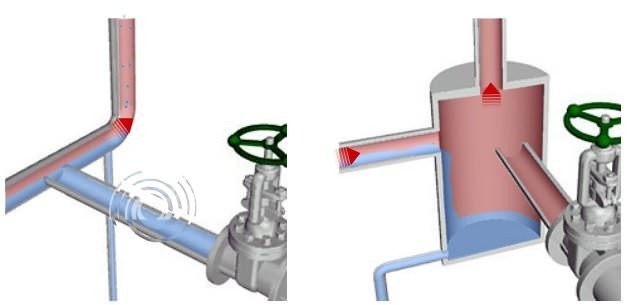

Other probable causes of water hammer include the accumulation of condensate in dead-end pipelines.

Only the most common cases are illustrated here. To completely eliminate water hammer in steam pipelines, it is necessary to inspect the entire pipeline system.

Option for upgrading the steam line tie-in

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442