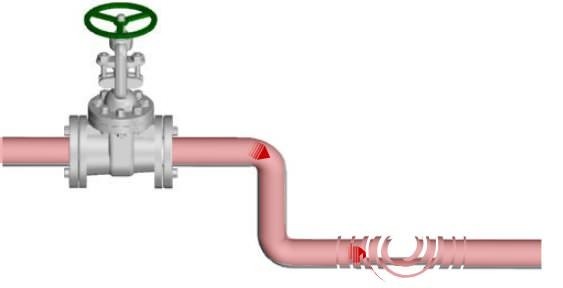

Everyone knows that in order to avoid water hammer, shut-off valves must open and close smoothly, especially in the "99% closed" position.

Water hammer does not disappear when the valve is closed.

But there are times when slow closing does not help and water hammer continues to occur even after the valve is completely closed.

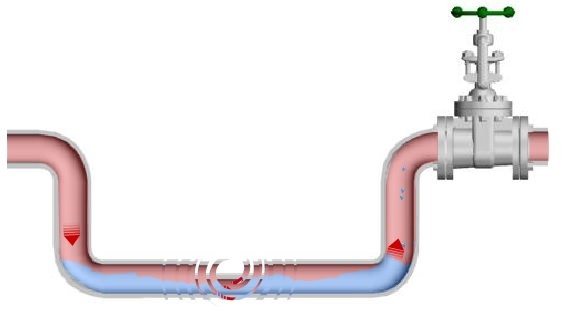

This is due to the instantaneous condensation of steam in the condensate present in the pipeline or due to the appearance of a wave in the same condensate.

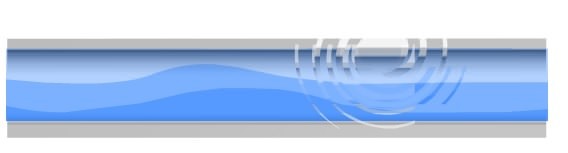

In steam lines, this is the result of lack or insufficient drainage. In the condensate pipeline, the wave is created by secondary boiling steam in cases where the diameter of the pipeline is narrowed as a result of incorrect calculation.

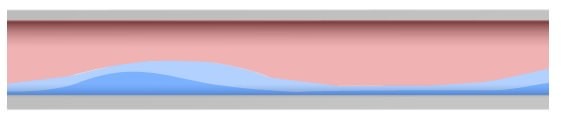

On straight sections (with no profile change), a wave leading to a water hammer is formed when the level of filling the pipeline with condensate exceeds 80% of its height (in cross section).

Therefore, when designing a network of condensate pipelines, it is necessary to take into account the presence of a two-phase medium in it. In this case, the calculation according to the principle of choosing the diameter of the water supply is not permissible.

Safety valve LESER 441/442 DN20/32

Safety valve LESER 441/442 DN20/32

Safety valve LESER 441/442 DN25/40

Safety valve LESER 441/442 DN25/40

Safety valve LESER 441/442 DN32/50

Safety valve LESER 441/442 DN32/50

Safety valve LESER 441/442 DN40/65

Safety valve LESER 441/442 DN40/65

Safety valve LESER 441/442 DN50/80

Safety valve LESER 441/442 DN50/80

Safety valve LESER 441/442 DN65/100

Safety valve LESER 441/442 DN65/100

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Float steam trap Yoshitake TSF-8-5 DN15

Float steam trap Yoshitake TSF-8-5 DN15

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Float steam trap Yoshitake TSF-8-5 DN25

Float steam trap Yoshitake TSF-8-5 DN25

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Float steam trap Yoshitake TSF-10F-10 DN15

Float steam trap Yoshitake TSF-10F-10 DN15

Shell and tube coolers

Shell and tube coolers