| Parameter name | Meaning |

|---|---|

| Finned tube material, plates | Steel, st. steel |

| Body material | Steel, st. steel |

| power, kWt | 100 ... 10000 |

| Inlet gas temperature, ° C | 250 ... 300 ° C, others on request |

| Outlet gas temperature, ° C | 50 ... 150 ° C |

| Water productivity, m 3 / h | 2 ... 200 |

| Pressure in the water circuit, bar | 10, 16, 25, 40 |

| Heat exchange surface area, m 2 | 100 ... 2500 |

| Aerodynamic resistance, Pa | 500 ... 8000 |

The waste heat exchanger is designed to cool flue gases, hot air of furnaces to the lowest possible temperatures and transfer heat to another heat carrier, as a rule, water, for heating for the needs of hot water supply, heating, ventilation.

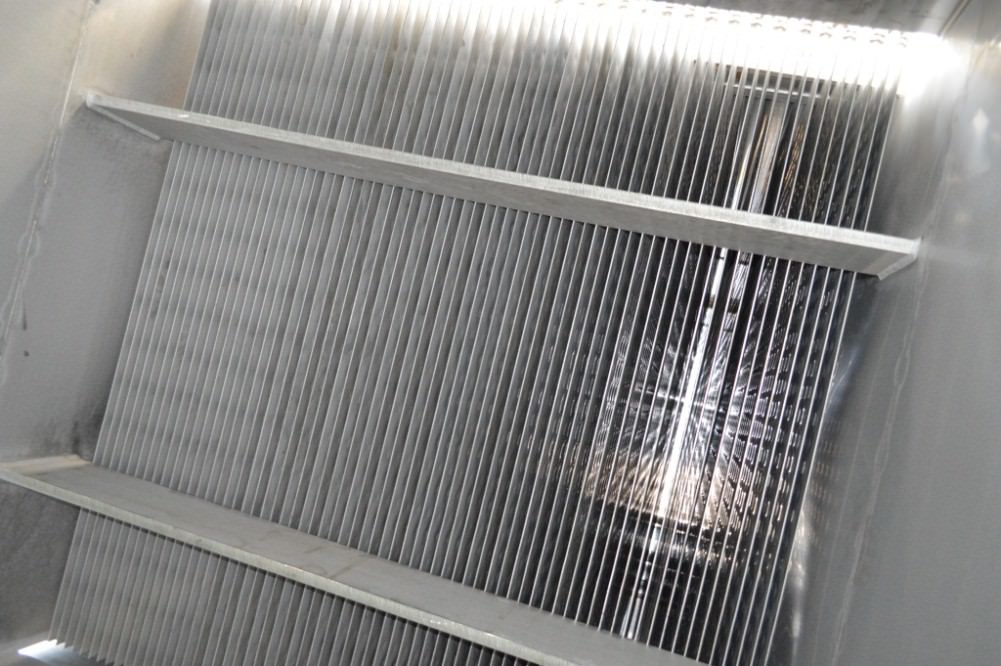

Waste heat exchangers or recuperators have been developed in which heat is exchanged between two gas streams. Structurally, a waste heat exchanger or cooler of flue gases consists of a heat exchange surface formed by corrugated steel sheets welded in pairs, forming two channels. One channel is for flue gases, the other is for the heated heating medium. Finned heat-resistant tubes can also be used as a heat exchange surface.

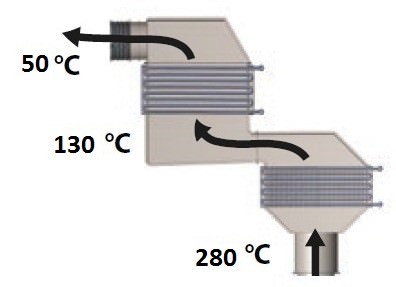

Cooling of flue gases can be carried out as standard from 250-280 ° C to 130-150 ° C. If the task is deeper cooling, then cooling is possible up to 50-55 ° C.

The main tasks that the installation of a flue gas heat exchanger solves:

- - increasing the degree of heat use at the enterprise;

- - saving fuel, which was used earlier to generate heat, which was uselessly emitted into the atmosphere;

- - reduction of thermal pollution of the environment;

- - creation of a more comfortable stay for personnel due to heating of industrial premises, availability of hot water for shower nets;

- - reducing the cost of production and increasing competitiveness.

The main tasks that the installation of a flue gas heat exchanger solves:

- - increasing the degree of heat use at the enterprise;

- - saving fuel, which was used earlier to generate heat, which was uselessly emitted into the atmosphere;

- - reduction of thermal pollution of the environment;

- - creation of a more comfortable stay for personnel due to heating of industrial premises, availability of hot water for shower nets;

- - reducing the cost of production and increasing competitiveness.

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard