| Parameter name | Meaning |

|---|---|

| Pipe material | Steel, st. steel |

| Finning material | Steel, st. steel |

| Pipe spacing in the tube sheet, mm | 4; 6; eight; other |

| Heat carrier | water vapor |

| Air throughput, nm 3 / h | 1000 ... 200000 |

| Maximum operating temperature, ºC | 400 |

| Pressure in the steam condensate circuit, bar | 10, 16, 25 |

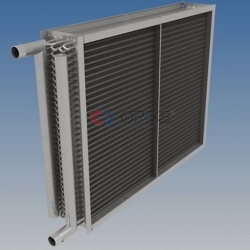

Steam heaters are used exclusively for heating air or gases. The source of thermal energy in this case is saturated water vapor. This type of heaters, as a rule, is single-pass and is installed vertically relative to the branch pipes, in order to ensure uniform steam condensation and condensate drainage.

A feature of the use of steam heaters is the need for a steam source. The most justified installation of steam heaters at industrial enterprises, equipped with steam lines for continuous steam supply. That is why large and small plants and factories often use steam heaters for heating air in workshops or for technical process tasks.

An important advantage is the ability of steam heaters to warm up the air the fastest for large voluminous rooms, even at negative temperatures inside the workshops. Structurally, the pipes used for the manufacture of steam heaters are chosen thicker, since the steam pressure and temperature inside the pipes can reach high values. The material is usually stainless steel.

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard