| Parameter name, characteristics | Value |

|---|---|

| Work environment | water |

| Nominal pressure | 10/16 bar |

| Temperature of the working environment | up to 160 С |

| Head losses | not more than 0.2 kg/cm2 |

| Connection | DN50-DN300 – flange/thread (flange according to GOST 12821, DIN2634, EN1092, ISO7005, JIS B2220); (threaded according to GOST 6357, DIN 259, EN 10226, ISO R228, JIS B 0202) G1/2-G2 – internal external thread |

| Installation | Vertical, the direction of the flow must coincide with the direction of the arrow on the body |

| Net weight, kg | 30-620 |

| - | Consumption of water, at 1 m/sec | Water consumption Hi-flow, at 3 m/sec | Volume | Hi-flow volume |

|---|---|---|---|---|

| Model | m3/h | m3/h | l | l |

| 50 | 8 | 25 | 5 | 7 |

| 65 | 15 | 40 | 5 | 7 |

| 80 | 20 | 55 | 17 | 25 |

| 100 | 30 | 95 | 17 | 25 |

| 125 | 50 | 145 | 50 | 75 |

| 150 | 75 | 220 | 50 | 75 |

| 200 | 125 | 360 | 105 | 150 |

| 250 | 200 | 575 | 210 | 300 |

| 300 | 275 | 810 | 350 | 500 |

Dirt in the heating and air conditioning system can cause significant damage to the equipment. Consequences - corrosion, functional disorders, premature wear of systems and equipment. Not surprisingly, filters are often used. This means that additional maintenance costs are inevitable. Filters become clogged and must be regularly cleaned, serviced, or replaced. Using a sludge separator will protect you from the need for constant maintenance.

The sludge separator OPEKS-1-SS of the industrial series is manufactured in a steel case with a diameter of 50 to 600 mm. The standard model is manufactured for a flow rate of up to 1.5 m3/h and the Hi-Flow model for a flow rate of up to 3m3/h. It is possible to perform both under welding and under flange connection.

For older systems with a high level of sludge, it may be necessary to replace or clean the separating element, for such cases a disassembled model is selected.

Application:

Automatic removal of dirt from the water of heating/cooling systems, water-glycol mixtures and production technical water. The product is not used for hazardous and flammable substances.

The principle of operation of the sludge separator

The device includes a special spiral that looks like a fine mesh. It filters out small particles: rust, sand, dirt, etc. All foreign particles settle in a special tank equipped with a drain valve, and they can be easily removed by draining a small amount of water. The simplicity of the design allows it to be used in various pipeline systems: the sludge separator is installed both in domestic and industrial installations.

One of the advantages is that the device can be used continuously. There is no need to replace the filters, the sludge separator can work without interruption for several decades. The mesh itself does not get clogged and does not oxidize during operation, so it will effectively filter various impurities.

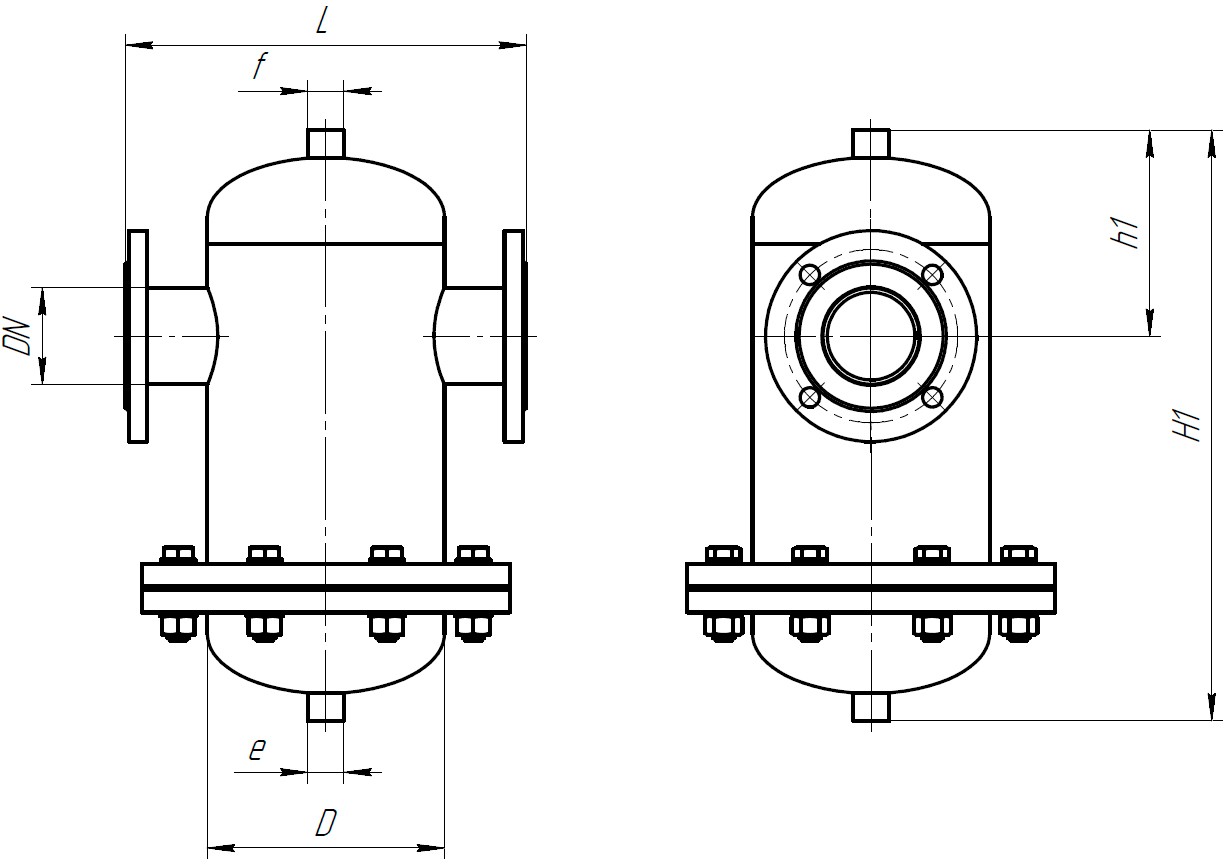

| Model | DN, mm | D, mm | L, mm | H1, mm | H2*, mm | h1, mm | h2*, mm | e, G | f, G |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 50 | 159 | 260 | 395 | 555 | 270 | 430 | 1 | 1 |

| 65 | 65 | 159 | 260 | 395 | 555 | 260 | 420 | 1 | 1 |

| 80 | 80 | 219 | 370 | 515 | 710 | 355 | 550 | 1 | 1 |

| 100 | 100 | 219 | 370 | 515 | 710 | 345 | 540 | 1 | 1 |

| 125 | 125 | 324 | 525 | 690 | 970 | 475 | 755 | 1 | 1 |

| 150 | 150 | 324 | 525 | 690 | 970 | 460 | 740 | 1 | 1 |

| 200 | 200 | 406 | 650 | 900 | 1240 | 615 | 955 | 1 | 1 |

| 250 | 250 | 508 | 750 | 1145 | 1645 | 800 | 1300 | 2 | 2 |

| 300 | 300 | 610 | 850 | 1360 | 1955 | 955 | 1550 | 2 | 2 |

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard