General specifications:

- Fully automatic filtration process

- Medium working pressure from 0.3 bar

- Effective cleaning of media from large volumes of contamination

- Protection of equipment from mussels and shells

- Energy savings due to minimal pressure loss

- Low operating costs

- Process control by time or pressure drop

- Connecting diameter up to DN800

- Media flow through the filter up to 8000 m3 / h

- Purification degree up to 150

- Wide range of body and internal materials ranging from special plastics to stainless steel

- Pneumatic or electric drive

- "Duplex" double versions of filters with manual or automatic control.

Main technical characteristics:

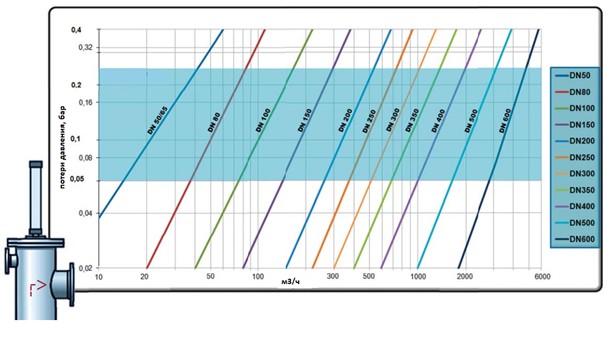

| Inlet pipe diameter DN | 50/65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 800 |

| Drainage pipe diameter DN | 25 | 40 | 40 | 50 | 80 | 100 | 100 | 150 | 150 | 150 | 200 | 250 | 250 |

| Max. flow (m3 / h) | 55 | 83 | 130 | 299 | 522 | 846 | 1170 | 1620 | 2088 | 3276 | 4680 | 6000 | 8500 |

| Flow rate at 0.1 bar resistance (m3 / h) | 28 | 53 | 85 | 180 | 340 | 490 | 710 | 960 | 1200 | 2000 | 2900 | 4000 | 5500 |

| Min. flow (m3 / h) | twenty | 38 | 60 | 140 | 250 | 350 | 500 | 690 | 900 | 1400 | 2000 | 2800 | 3700 |

| Min. drainage flow (m3 / h) | 6 | nine | fourteen | 32 | 61 | 94 | 133 | 180 | 241 | 380 | 540 | 740 | 930 |

| Max. contamination size (μm) | ten | ten | ten | twenty | twenty | twenty | twenty | thirty | thirty | thirty | thirty | thirty | thirty |

| Flow velocity (m / s) | 3 | <2 | 3 | 4 | > 3 | <3 | > 4 | 2.5 | 3.6 | > 5 | 4.5 | 4.1 | 5.3 |

| Head loss in the drain line (bar / m) | 0.04 | 0.02 | 0.03 | 0.04 | 0.02 | 0.01 | 0.02 | 0 | 0.01 | 0.02 | 0.01 | 0.01 | 0.01 |

| Air consumption (l / s) (for pneumatic drive) | 0.2 | 0.3 | 0.3 | 0.8 | 0.8 | 4 | 4 | eight | eight | eighteen | eighteen | 35 | 35 |

| Set differential pressure across the grid | 0.11 bar | ||||||||||||

The F450 filter is designed for all low viscosity liquids and automatically cleans itself, which simultaneously saves time and money compared to manual cleaning that requires interrupting the filtration process.

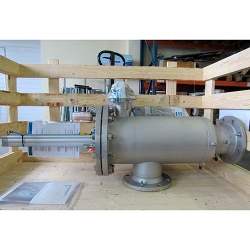

The filter can be installed in hard-to-reach areas of piping systems. The big advantage of the F450 filter is that it can operate at low pressures from 0.3 bar, in contrast to conventional mechanical filters that require a working pressure of 3-4 bar.

The F450 filter is designed to protect heat exchange equipment and piping systems from contamination. Due to the high turbulence at the surface of the filter mesh, organic components in the dirt are destroyed. For example, shells and mussels have the best growth conditions in heat exchange equipment, impairing heat transfer, increasing hydraulic resistance and ultimately blocking the heat exchanger. In this case, the filter ensures the normal functioning of the entire system.

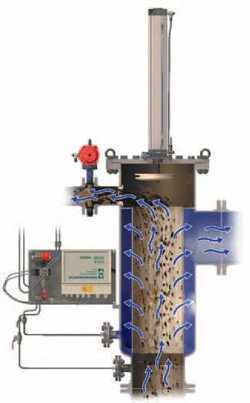

| Filtration Dirt particles accumulate in the mesh from top to bottom. |

| Filtration and 1st stage of cleaning The timer or pressure switch is triggered, the relief valve opens, through which the largest particles of contamination begin to be carried away by the lifting flow. |

| Filtration and 2nd cleaning stage The cleaning disc is lowered into the mesh, creating a Bernoulli effect, pulling dirt away from the mesh. The disc is lowered only by 2/3 of the length of the filtering mesh, the flow area of the filter is free, the filtration process continues continuously. Particles of contamination are removed into the waste pipeline. |

| Filtration and the 3rd stage of cleaning The disc returns to its original place, the speed of the medium increases in the lower 2/3 of the filter, reducing the static pressure inside the mesh in comparison with the pressure outside the mesh (in the clean area), a counterflow is formed, which tears off the residual contamination in the lower 2 / 3 parts of the filter. The cleaning process is complete. |

- Medium consumption;

- Maximum operating temperature;

- Maximum working pressure;

- Maximum allowable pressure loss;

- The size of the particles to be filtered;

- Water - fresh or sea water;

- Drive type - electric or pneumatic;

- Requirements for vibration resistance;

- Horizontal or vertical design.

Main advantages:

- Effective protection of large systems, processes and chilled water installations

- Minimum maintenance

- Prevents damage and clogging of heat exchangers and cooling units

- Eliminate downtime

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard