Modern manufacturing facilities

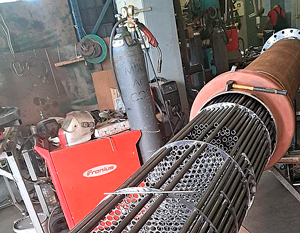

OPEKS Energysystems produces energy-efficient plate and shell-and-tube heat exchangers, heat recovery units, air heaters, modular heat substations, tank equipment, and a wide range of thermal engineering products at its own production sites.

Our plant is organized to simultaneously perform many technological processes, optimizing time and reducing the production periods of parts and finished products. Full equipment with a modern machine park ensures the execution of all key production operations.

Main technological processes

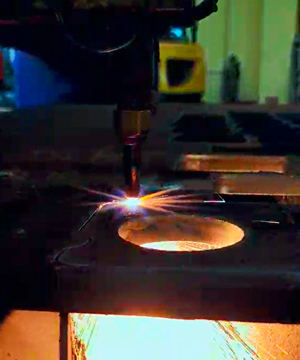

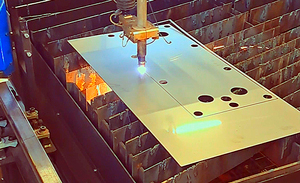

Metal cutting and profiling

- CNC plasma cutting machines allow the production of pressure plates for plate heat exchangers, tube sheets for shell-and-tube models, and other large elements.

- Stainless steel blanks are also processed on laser cutting machines, which guarantees precision and high quality of parts.

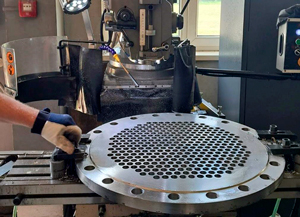

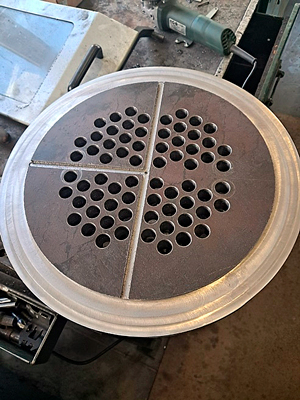

Milling and drilling operations

- Used for the production of tube sheets, pressure plates, and body elements.

- Ensure high processing accuracy and reliable connections.

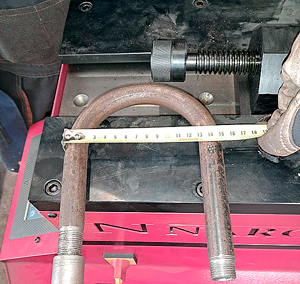

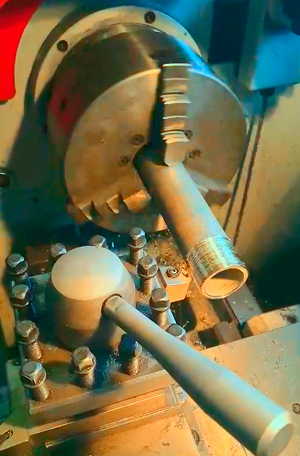

Turning and pipe-bending operations

- Turning, threading, and pipe-bending machines are used for the production of nozzles, cylindrical parts, and pipeline elements.

- These operations are especially important for boilers, water heaters, and heat substations.

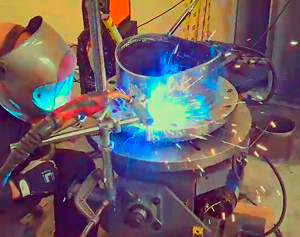

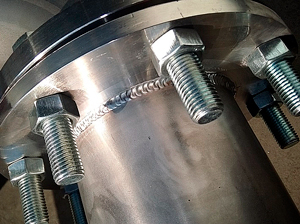

Welding operations

- Professional welding equipment and experienced specialists transform blanks into finished equipment.

- Vessels, frames, heat exchangers, and substation frames are manufactured from both carbon and stainless steels of grades AISI 316/316L and AISI 304/304L.

Surface preparation and painting

- All parts undergo cleaning: rust removal, degreasing, sandblasting.

- Painting is carried out in a specialized chamber with professional spray-painting equipment, in strict compliance with project documentation.

Assembly and final operations

- Assembly areas are equipped with lifting mechanisms and specialized tooling.

- This ensures convenience, precision, and speed during the final assembly of products.

Quality control and standards

- Quality control is carried out at all stages — from metal preparation to final assembly.

- Only certified materials and world-class components are used.

- All products comply with project documentation requirements and energy efficiency standards.

Advantages of our production

- Full production cycle in one place.

- Reduced equipment manufacturing times.

- Possibility of implementing individual projects.

- Experienced specialists and a modern machine park.

- Guaranteed reliability and energy efficiency of products.

Who we manufacture for

Our production capabilities serve clients from various industries — from municipal energy and utilities to industry and business. Thanks to our own production, we provide not only high product quality but also flexibility in solving non-standard tasks.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Float steam trap Yoshitake TSF-8-5 DN15

Float steam trap Yoshitake TSF-8-5 DN15

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN50 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN40 А/0.05-0.9MPa

Float steam trap Yoshitake TSF-8-5 DN25

Float steam trap Yoshitake TSF-8-5 DN25

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN32 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN15 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN25 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN65 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-1000EN DN100 А/0.05-0.9MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN25 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Reducing valve for steam Yoshitake GP-2000EN DN50 B/0.1-1.4MPa

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 10 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 20 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 30 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 40 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 50 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 60 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 70 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 80 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 90 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 100 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 110 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 120 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 130 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 140 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Plate heat exchanger THERMAKS РТА (GC)-16, 150 plates

Float steam trap Yoshitake TSF-10F-10 DN15

Float steam trap Yoshitake TSF-10F-10 DN15

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442