To exclude the flooding of heat exchange equipment with condensate, it is necessary to ensure the lowest possible back pressure in the condensate line after the condensate drain , and ideally, to completely reduce it to zero. This is ensured by the correct selection of the diameter of the condensate line and the reduction of its length, as well as minimization, up to the elimination of static pressure. How to implement this?

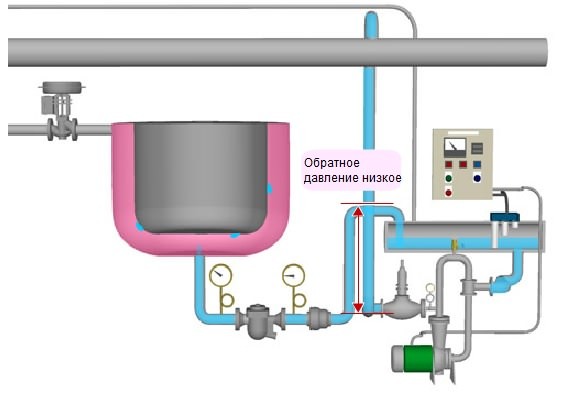

The most common method is to collect condensate in an open container, followed by pumping it into the boiler room using a centrifugal pump.

This scheme allows you to limit the length of the condensate line from the equipment, the distance to the collecting tank, and not to the boiler room. The static back pressure of the condensate is determined by the installation height of the tank. It should also be noted that in order to exclude cavitation in a centrifugal pump, it is necessary to provide for a minimum installation height of the tank, which will accordingly increase the back pressure value after the condensate drain.

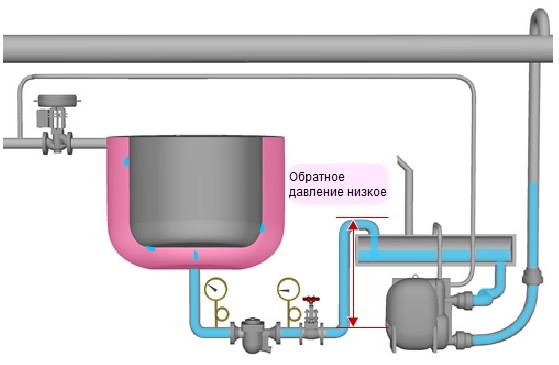

This disadvantage is eliminated in the following scheme, in which a mechanical TLV GP-series pump is used instead of a centrifugal pump. It uses the principle of displacing condensate, and uses steam as a driving force, so cavitation is excluded here. And the installation height of the condensate collection tank can be minimal, and with it the back pressure value.

However, this scheme is not ideal from the point of view of energy efficiency, since the condensate discharged at the saturation temperature and getting into the open collecting tank begins to boil. In this case, a large volume of flash steam is formed, which is simply discharged into the atmosphere.

One of the most advanced, reliable and energy efficient methods is the installation of TLV type GT pumping steam traps. Here, in one device, the functions of a steam trap and a mechanical pump are combined, while there is no need to use rather bulky containers. And most importantly, the condensate is returned to the boiler room at a high temperature, eliminating boiling and saving more energy.

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442