| MPS 3 | MPS | |

| Maximum operating temperature 100 ° C | ||

| Anti-corrosion coating | Raw inside | |

| Insulation | Flexible PU insulation, colored PVC outer lining with zipper, with plastic lid | |

| Pressure | 3 bar | 6 bar |

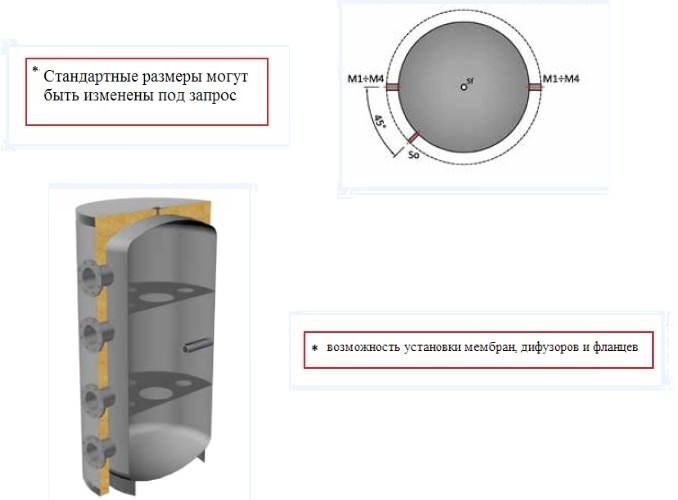

| Application | Accumulation of hot drinking water of high temperature due to the use of special insulation aimed at eliminating heat loss. To heat the water, a heat exchanger is used, which is installed outside the tank. The circulation of water between the heat exchanger and the tank is provided by a circulation pump with a body made of bronze or stainless steel, this is due to the presence of air in the pipelines that cause corrosion. The tank also has an inspection hatch for auditing. |

| Execution | High quality sheet steel type S235JR EN10025 is assembled and welded by automatic welding. |

| Anti-corrosion coating | Internal anti-corrosion coating made of CERAMPLAST on a micro-ceramic base, used for work in aggressive environments with high temperatures, in installations with solar collectors, at a sharp increase in temperature, in order to avoid the spread of legionella bacteria. Fully complies with the requirements for drinking water according to DM 174/2004 (Italian standards) and the CEE directive 76/893. Maximum operating temperature 110 ° C. |

| Cathodic protection | Art. HOT / J threaded magnesium anode. Art. HOT / J-PLUS: electronic anode for permanent cathodic protection. |

| Insulation and type of outer cover | Art. HOT / J: flexible polyurethane, PVC outer cover with zipper and thermal cover. Art. HOT / J-PLUS: removable polyurethane cover, PVC outer cover with zip and thermal cover (up to 6000 liters) |

| Certificates | Complies with directive 97/23 / CE Art. 3 - Part 3 |

| Supplement on request | |

| Horizontal execution: | price increase by 8% |

| Insulation thickness 200 mm: | price increase by 40% |

| Resizing: | on request |

| Aperture setting: | on request |

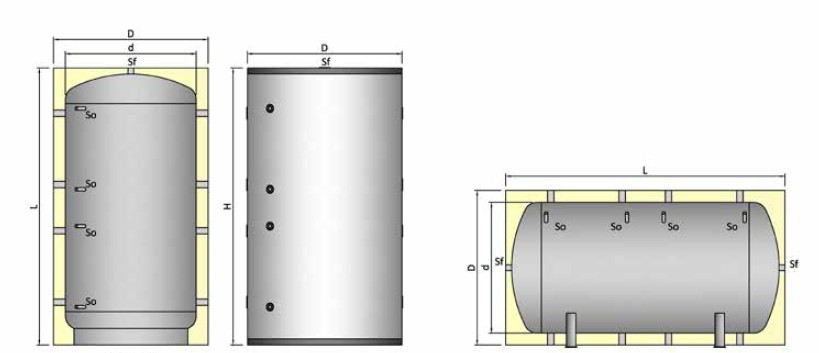

Accumulation tanks represent a vertical (or horizontal) welded structure, consisting of a cylindrical shell, upper and lower (left and right) elliptical bottoms, a fitting for supplying and removing the working medium and drainage of the system, as well as a fitting according to the project or at the request of the customer. Supports are welded to the lower bottom (shells - in horizontal design) for reliable installation on site.

Storage tanks are used as heat or cold accumulators, buffer tanks, water heaters. Designed for: heating, accumulation of thermal energy in the form of hot water, hydraulic decoupling of flows in the circuits of technological systems of industrial enterprises, hot water supply and heating systems, storage and transfer of excess heat received from the source (electric boiler, solid fuel boiler, heat pump, solar collectors, solar systems) with the ability to connect several sources of thermal energy.

- increase in the service life of the heating system;

- reduction of fuel consumption by 30-40%;

- increase in the service life of the heating system;

- reducing the risk of boiling a solid fuel boiler;

- the ability to maintain a constant temperature;

- combining different types of heat energy;

- extension of the interval between boiler cleanings, easy installation into the existing heating system.

| Model | 30,000 | ||

| d | Diameter without insulation | mm | 2500 |

| D | Insulated diameter | mm | 2700 |

| HT | Height | mm | 6900 |

| Connections | |||

| M1-M4 | Connections | G4 " | |

| Sf | Leaving water connections | G1½ " | |

| So | Sensor connection | G½ " |

To select the required storage volume, it is possible to combine several tanks into a cascade.

The storage tank is selected for the previously selected heat source and is calculated in such a way that it can accumulate all the heat generated by this source, or for the consumer of which it should be provided with heat generated before the time of heat consumption by a low-power source.

The priority in the selection of the capacity will be the source if its power or the time of heat input is limited.

The priority in the selection of the capacity will be the consumer, if it is required to cover a given heat load in a certain time.

The additional volume of water formed during heating to the maximum temperature is ~ 3.5% of the nominal volume of the container.

- security group;

- level / temperature / pressure sensors;

- thermoelectric heater;

- heat exchanger;

- insulation in the cold;

- cathodic protection;

- service;

- inspection hatch; leather / fabric cover;

- development of individual equipment *

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard