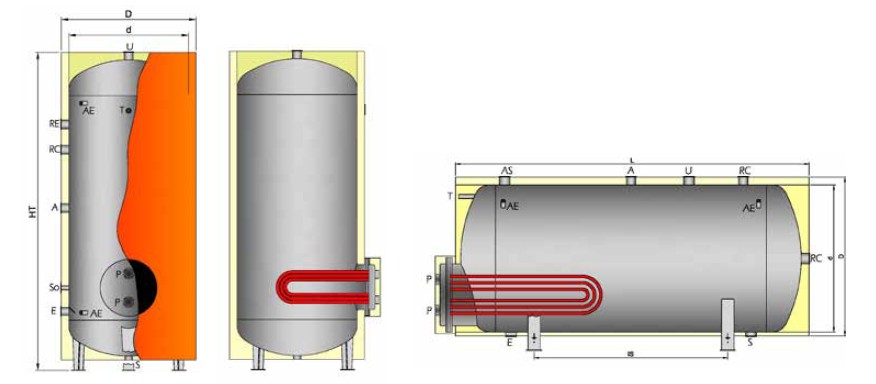

| APPLICATION | Heating and storage of hot potable water (heated circuit) by means of a removable U-shaped heat exchanger (heating circuit) and natural convection. Hot water, steam or recovered heat (heat recovery system), condensate, etc. can be used as a heating circuit. The correct assessment of the hot water demand and the correct choice of tank capacity can lead to significant energy savings. |

| EXECUTION | TANK mod. QB / X, HBX is made of high quality S235JR EN10025 carbon steel, assembled and welded by automatic welding. HEAT EXCHANGER made of stainless steel, “U” type, welded to the plate, complete with EPDM gasket. |

| ANTI-CORROSIVE COATING | Art. HBX 1000-3000: enamelled internal anticorrosive coating (Enamel), suitable for drinking water use in accordance with Italian directives DM 174/2004 and Dir. CEE 76/893. Art. HBX 4000-5000: internal anti-corrosion coating made of CERAMPLAST on a micro-ceramic base, suitable for use in aggressive environments with high temperatures, in installations with solar collectors, in case of sudden temperature increases, in order to prevent the spread of legionella bacteria. Fully complies with the requirements for drinking water according to DM 174/2004 (Italian standards) and the CEE directive 76/893. Maximum operating temperature 100 ° C. |

| CATHODE PROTECTION | Art. QB / X, HBX threaded magnesium anode. |

| INSULATION AND COATING TYPE | Art. QB / X, HBX and XN / X flexible polyurethane, PVC outer cover with zip and thermal cover Mod. QB / X-PLUS, HBX-PLUS and XN / X-PLUS Removable rigid polyurethane casing, PVC outer cover with zip and thermal cover. |

| CERTIFICATES | Complies with directive 97/23 / CE Art. 3 - Part 3. |

| Supplement on request | |

| Horizontal execution: | price increase by 10% |

| Model | 200 | 300 | 500 | 800 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | ||

| Volume | l | 185 | 295 | 500 | 795 | 920 | 1435 | 1980 | 2605 | 2910 | 3710 | 4945 | |

| d | Diameter without insulation | mm | 450 | 550 | 650 | 800 | 800 | 950 | 1100 | 1250 | 1250 | 1400 | 1600 |

| D | Insulated diameter | mm | 550 | 650 | 750 | 900 | 900 | 1050 | 1200 | 1350 | 1350 | 1500 | 1700 |

| HT | Height | mm | 1370 | 1420 | 1730 | 1810 | 2060 | 2390 | 2430 | 2500 | 2750 | 2800 | 2830 |

| L | Length (horizontal design) | mm | 1310 | 1390 | 1670 | 1730 * | 1980 | 2300 | 2370 | 2440 | 2680 | 2780 | 2860 |

| IS | Distance between supports (horizontal version) | mm | 840 | 840 | 1090 | 1010 | 1230 | 1510 | 1510 | 1470 | 1720 | 1720 | 1720 |

| FL | Inspection hatch diameter (QB / X, XN / X) | mm | 220 × 300 | 300 × 380 | 350 × 430 | ||||||||

| SS1 | Tubular heat exchanger heating area (QB / X) | m 2 | 0.50 | 0.75 | 1.00 | 1.50 | 2.00 | 3.00 | 4.00 | 5.00 | 6.00 | 8.00 | 10.00 |

| FL | Inspection hatch diameter (HBX) | mm | - | - | - | 220 × 300 | 400 × 480 | ||||||

| SS1 | Tubular Heat Exchanger Heating Area (HBX) | m 2 | - | - | - | 1.50 | 2.00 | 3.00 | 4.00 | 5.00 | 6.00 | 8.00 | 10.00 |

| K | Maximum tilt height | mm | 1557 | 1625 | 1922 | 2079 | 2307 | 2592 | 2701 | 2823 | 3045 | 3176 | 3305 |

| Weight, 6 bar | Kg | - | - | - | - | - | 240 | 295 | 345 | 380 | 555 | 660 | |

| Weight, 8 bar | Kg | 60 | 75 | 90 | 135 | 175 | 300 | 365 | 430 | 475 | 770 | 790 | |

| Weight, 10 bar | Kg | 75 | 95 | 115 | 175 | 200 | 360 | 440 | 515 | 565 | 895 | 915 | |

| Connections | |||||||||||||

| E | Cold water inlet | G1 "¼ | G1 "¼ | G1 "¼ | G1 "½ | G1 "½ | G2 " | G2 " | G2 "½ | G2 "½ | G3 " | G3 " | |

| U | Hot water outlet | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G2 " | G2 " | G2 "½ | G2 "½ | G3 " | G3 " | |

| RC | Recirculation | G1 "¼ | G1 "¼ | G1 "¼ | G1 "½ | G1 "½ | G2 " | G2 " | G2 "½ | G2 "½ | G3 " | G3 " | |

| RE | Electric heating element | G1 "¼ | G1 "¼ | G1 "¼ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G2 " | G2 " | G2 " | G2 " | |

| P | Heating circuit | G1 " | G1 " | G1 " | G1 "½ | G1 "½ | G1 "½ | G2 " | G2 " | G2 " | G2 " | G2 " | |

| S | Draining | G½ " | G½ " | G½ " | G½ " | G½ " | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | |

| A | Magnesium anode | G1 "¼ | G1 "¼ | G1 "¼ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | |

| T | Thermometer / thermostat | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | |

| AE | Electronic anode | - | - | - | - | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | |

| So | Sensor | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | |

| Technical details | |||||||||||||

| PE | Maximum working pressure of the tank | bar | eight | eight | eight | eight | eight | 6 | 6 | 6 | 6 | 6 | 6 |

| PC | Tank test pressure | bar | 12 | 12 | 12 | 12 | 12 | nine | nine | nine | nine | nine | nine |

| Maximum working pressure of the heat exchanger | bar | nine | nine | nine | nine | nine | nine | nine | nine | nine | nine | nine | |

| Heat exchanger test pressure | bar | fourteen | fourteen | fourteen | fourteen | fourteen | fourteen | fourteen | fourteen | fourteen | fourteen | fourteen | |

| TE | Continuous operating temperature (QB / X) | ° C | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 | 65 |

| TE | Peak temperature (QB / X) | ° C | 81 | 81 | 81 | 81 | 81 | 81 | 81 | 81 | 81 | 81 | 81 |

| TE | Maximum operating tank temperature (XN / X, HBX) | ° C | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| TE | Maximum operating temperature of the heat exchanger | ° C | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard