Flashback steam is generated when hot condensate or boiler water enters a low pressure environment (below the saturation pressure). Under such conditions, the liquid boils, and a certain part of it turns into secondary boiling vapor. This process mainly takes place after steam traps and in condensate collection tanks.

The use (disposal) of secondary steam can significantly increase the energy efficiency of the steam condensate system.

How is flashback vapor generated?

Steam is generated because the saturation point of the water changes with pressure. For example, the saturation point of water at atmospheric pressure is 100 ° C, but at a pressure of 1.0 MPa (10 bar g), it will already be 184 ° C.

So what happens when a pressurized condensate with a temperature of 184 ° C is discharged into the atmosphere?

In this case, in order to compensate for the excess amount of energy (enthalpy), some of the water molecules release it in the form of latent heat and evaporate to form steam. This will reduce the temperature of the liquid until it reaches the saturation point of 100 ° C.

How to determine the amount of flash steam?

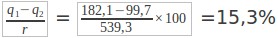

The amount of secondary steam can be determined by the formula:

q1 - heat (enthalpy) of the condensate at a higher pressure (before its release) q2 - heat (enthalpy) of the condensate at a lower pressure (where the outlet is carried out) r - latent heat of vaporization at a lower pressure

For the above example:

| Absolute pressure, bar | Temperature, ° C | Heat of liquid, kcal / kg | Latent heat of vaporization, kcal / kg | Total heat of steam, kcal / kg |

|---|---|---|---|---|

| 1.0 | 99.6 | 99.7 | 539.3 | 639.0 |

| 2.0 | 120.2 | 120.5 | 525.9 | 646.4 |

| 3.0 | 133.5 | 134.1 | 516.7 | 650.8 |

| ten | 179.9 | 182.1 | 481.0 | 663.1 |

| eleven | 184.1 | 186.5 | 477.4 | 663.9 |

| 12 | 188 | 190.7 | 473.9 | 664.6 |

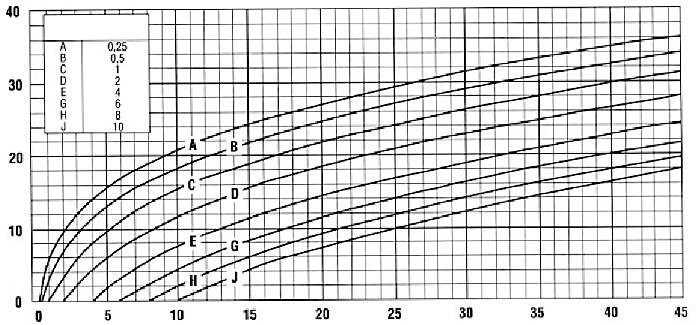

For an approximate calculation, you can use the diagram: Percentage of flash steam,%

Condensate pressure, bar

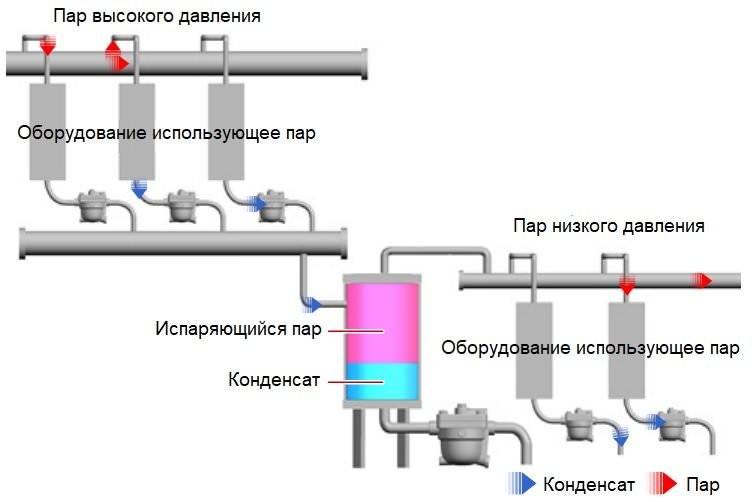

What to do with flash steam?

Secondary steam is a by-product of the operation of steam systems. Since its nature does not differ from live steam, it is advisable to introduce systems for its reuse and disposal, both at the design stage and during the modernization of existing steam systems. This allows you to get the most effective energy saving indicator and the fastest payback.

Example of utilization of secondary steam using a flashback vessel

There are also other methods of disposal - this is the use of steam compressors or the use of a closed system in which the condensate does not come into contact with the atmosphere, but is discharged under pressure directly into the boiler room .

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

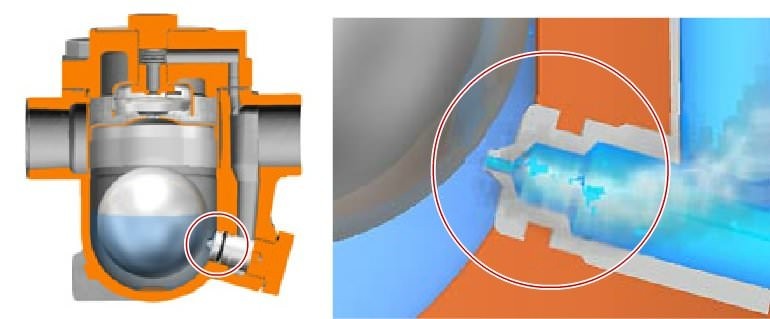

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442