| Model |

|

| 220/100 | 330/150 | 600/100 | 600/180 | 800/180 | 800/300 | 1000/180 | 1000/300 | 1500/300 | 2000/300 |

| Tank capacity | l | 220 | 330 | 575 | 575 | 796 | 796 | 900 | 900 | 1462 | 1996 |

| Actual tank capacity | l | 120 | 150 | 472 | 347 | 621 | 501 | 743 | 605 | 1167 | 1605 |

| The actual capacity of the potable water heating tank | l | 100 | 100 | 100 | 175 | 175 | 295 | 175 | 295 | 295 | 295 |

| D | External tank diameter (insulated) | mm | 600 | 600 | 750 | 750 | 990 | 990 | 990 | 990 | 1150 | 1300 |

| d | External tank diameter (without insulation) | mm | 500 | 500 | 650 | 650 | 790 | 790 | 790 | 790 | 790 | 1100 |

| HT | Height | mm | 1385 | 1860 | 1910 | 1910 | 1805 | 1805 | 2105 | 2105 | 2320 | 2390 |

| Heating area of the bottom spiral heat exchanger | m 2 | 1.4 | 2.0 | 2.4 | 2.4 | 2.6 | 2.6 | 3.0 | 3.0 | 4.1 | 4.5 |

| Heating area of the upper spiral heat exchanger | m 2 | - | - | 2.0 | - | 3.0 | - | 3.0 | - | 4.5 | 4.5 |

| Tank weight mod. KOMBI | Kg | 85 | 110 | 140 | 150 | 180 | 200 | 220 | 240 | 270 | 330 |

| Tank weight mod. KOMBI-S | Kg | 95 | 120 | 150 | 160 | 210 | 230 | 250 | 270 | 300 | 330 |

| Tank weight mod. KOMBI-SS | Kg | - | - | 190 | - | 230 | - | 270 | - | 340 | 390 |

| Tank connections |

|

|

|

|

|

|

|

|

|

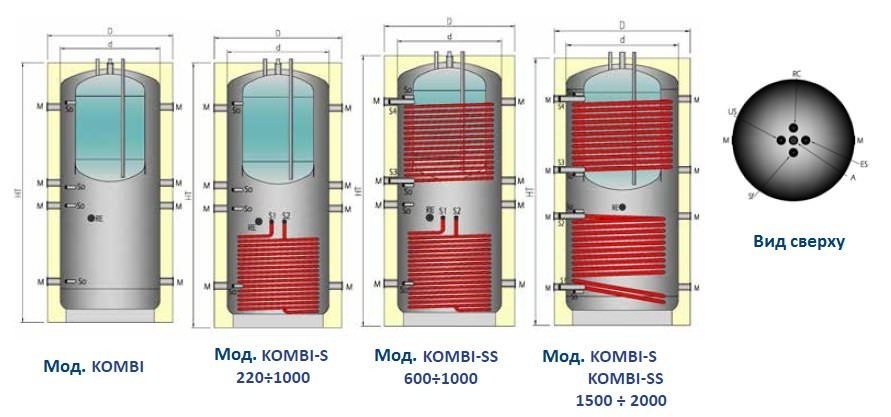

| M | Connections to external sources |

| G1 "¼ | G1 "¼ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ |

| RE | Connection for additional electric heating element |

| G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ | G1 "½ |

| Sf | Air valve |

| G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " | G½ " |

| S1-S2 | Inlet-outlet of the lower spiral heat exchanger |

| G¾ "M | G¾ "M | G¾ "M | G¾ "M | G¾ "M | G¾ "M | G¾ "M | G¾ "M | G1 "¼ | G1 "¼ |

| S3-S4 | Upper spiral heat exchanger connections |

| - | - | G1 " | G1 " | G1 " | G1 " | G1 " | G1 " | G1 "¼ | G1 "¼ |

| Hot water tank connections |

|

|

|

|

|

|

|

|

|

| ES | Cold water inlet |

| G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " |

| US | Hot water outlet |

| G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " |

| RC | Recirculation |

| - | - | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " | G¾ " |

| A | Magnesium anode |

| G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ | G1 "¼ |

| RE | Electric heating element |

| G1 "¼ | G1 "¼ | - | - | - | - | - | - | - | - |

| Technical details |

|

|

|

|

|

|

|

|

|

| PE | Maximum working pressure of the heated circuit (DHW) | bar | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| PC | Heating circuit test pressure (DHW) | bar | nine | nine | nine | nine | nine | nine | nine | nine | nine | nine |

| TE | Max. working temperature | ° C | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| PST | Maximum working pressure of the tank | bar | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| PSC | Tank test pressure | bar | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 |