| Parameter name | Meaning |

|---|---|

| Distance between 2 sheets forming a channel, mm | 5 - 70 |

| Width of sheets forming a channel, mm | 50 - 2000 |

| Heat exchange surface of the apparatus, m 2 | 0.1 - 800 |

| Sheet thickness, mm | 2 - 8 |

| Case (casing) sheet thickness, mm | 4 - 30 |

| Working pressure, bar | from vacuum to 45 |

| Working temperature, С | -100 - + 450 |

| Case diameter, mm | 250 - 2600 |

| Materials (edit) | carbon steels, stainless steels, aluminum alloys, nickel alloys, titanium, zirconium, others |

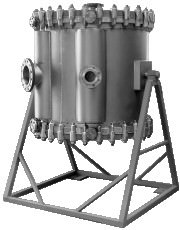

Spiral heat exchangers from OPEKS ENERGYSYSTEM

Purpose: solving the problem of heat transfer between media with a high degree of viscosity and contamination, including heat carriers containing solid fibers or particles of different nominal diameters in the volume.

Advantages of spiral heat exchangers:

- Suitable for “problematic” media such as highly contaminated liquids, aggressive and highly viscous media, etc.

- High operating efficiency over the entire load range.

- Low pressure loss.

- Compactness, respectively, saving useful space.

- Easy cleaning of deposits by mechanical or chemical washing methods.

- A wide range of flow types and channel types.

- Reduced operating costs for shutdowns as cleaning is much less frequent and easier than with other types of heat exchangers.

The task of carrying out heat exchange between very dirty or very viscous media has always been difficult. The peculiarity of such processes lies in low heat transfer coefficients, which in turn leads to low heat transfer coefficients and requires huge heat exchange surfaces. Most of the above problems have been solved with the advent of spiral heat exchangers. The inventor decided to twist the sheet of steel into a spiral and direct the flows on both sides of the wall of the sheet of steel. The idea turned out to be very convenient, since it allows you to change the distance between the steel sheets depending on the degree of viscosity or contamination of the heat carriers involved in heat exchange in the spiral heat exchanger. This idea made it possible to clean the spiral heat exchangers in a simple way, by opening the covers on both sides of the heat exchange surface and flushing the entire heat exchange surface through the light.

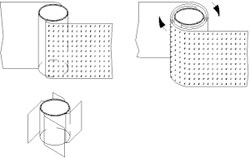

Spiral heat exchanger concept

Built on twisting 2 or 4 strips of metal around the central pipe, the strips are welded together using dividing pins at a certain distance, creating 2 or 4 channels of uniform width. The central pipe is divided into 2 parts, forming an inlet and outlet manifold. The entire structure is housed in a cylindrical body. The outer ends of the sheets are welded along the manifolds, forming the remaining two inlet and outlet pipes on the side of the body.

The media move in concentric circles in the channels, and the spacer pins create significant turbulence at low speeds and correspondingly low Reynolds numbers (Re), this design feature allows high heat transfer to be achieved even for viscous and very dirty media. High turbulence in the channels reduces the build-up of contaminants. The listed factors make it possible to manufacture compact heat exchangers, reducing their cost of metal consumption.

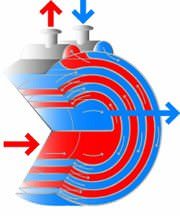

Heat transfer modes

The streams can move in different directions, fulfilling one or another requirement of the heat transfer regime:

- Type A. Counter flow or single direction flow. Suitable for liquid / liquid or vapor / liquid media

- Type B. Cross current. It is used in devices where it is necessary to evaporate or condense any medium

- Type B. Mixed current (type A and type B). It is used in condensers with the possibility of subcooling the medium.

The geometry of the channels can vary within wide limits, it can be, for example, a narrow and long channel, smoothly twisted into a spiral. The thermal length of the duct can be calculated for conditions with a temperature difference between media of less than 2 ° C! This design allows for efficient heat exchange between "complex" media that block any other heat exchangers, since the flow can travel a fairly large distance in the channel without making sharp turns, without creating stagnant zones.

Robust all-welded construction, no welds in hard-to-reach places of the heat exchanger, the ability to easily clean heat exchange surfaces, low hydraulic resistance make spiral heat exchangers an indispensable solution for a variety of technological processes.

Delivery

- Pickup from a warehouse in Kiev - is free

- New Mail - at the rates of the delivery service, at the rates of the delivery service, at the rates of the delivery service

- SAT - at the rates of the delivery service

- Deliveri - at the rates of the delivery service

Payment

- Cashless payment with VAT

- Online Privat24, Visa / MasterCard