Steam injectors

Steam injector Yoshitake MS-1

Steam injector Yoshitake MS-1

- Manufacturer: Yoshitake

- Max. operating pressure: 0.7 MPa

- Max. sound damping temperature: 60 °C

- Material: cast bronze/cast stainless steel

Steam injector Yoshitake MS-3

Steam injector Yoshitake MS-3

- Manufacturer: Yoshitake

- Max. operating pressure: 0.7 MPa

- Max. sound damping temperature: 60 °C

- Material: cast bronze/cast stainless steel

Steam injector Yoshitake MS-2

Steam injector Yoshitake MS-2

- Manufacturer: Yoshitake

- Max. operating pressure: 0.7 MPa

- Max. sound damping temperature: 90 °C

- Material: cast bronze/cast stainless steel

Steam injector Yoshitake MS-4

Steam injector Yoshitake MS-4

- Manufacturer: Yoshitake

- Max. operating pressure: 0.7 MPa

- Max. sound damping temperature: 90 °C

- Material: cast bronze/cast stainless steel

Steam injector Yoshitake MS-6

Steam injector Yoshitake MS-6

- Manufacturer: Yoshitake

- Max. operating pressure: 0.7 MPa

- Max. sound damping temperature: 90 °C

- Material: cast stainless steel

Individual heating station of the heating system according to an independent connection scheme

Individual heating station of the heating system according to an independent connection scheme

Reducing valve for steam Yoshitake GP-1000EN

Reducing valve for steam Yoshitake GP-1000EN

Float steam trap Yoshitake TSF-10

Float steam trap Yoshitake TSF-10

Centrifugal steam separator OPEKS-1-SC16-1-F50

Centrifugal steam separator OPEKS-1-SC16-1-F50

Plate heat exchanger THERMAKS РТА (GC)-16

Plate heat exchanger THERMAKS РТА (GC)-16

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25T

Brazed heat exchanger SWEP B25THx20

Brazed heat exchanger SWEP B25THx20

Shell and tube coolers

Shell and tube coolers

Safety valve LESER 441/442

Safety valve LESER 441/442

Steam injector

Steam injector concept. Varieties

In its most general form, a steam injector is a device designed to inject water vapor into another medium, usually liquid water. Steam injectors have a rather narrow thermal engineering application, since in order to ensure their efficient operation they must be in close proximity to the steam generator. Mainly, as a part of equipment for steam boilers, or in systems for utilizing thermal energy of excess water vapor through heated water.

A steam injector (steam injector) is called two types of devices that differ significantly in design and purpose:

- Steam injectors designed to inject make-up water (more precisely, its mixture with live steam) into a steam boiler.

- Steam injectors designed to inject low-potential water vapor into cold water in an open container under atmospheric pressure, in order to heat it.

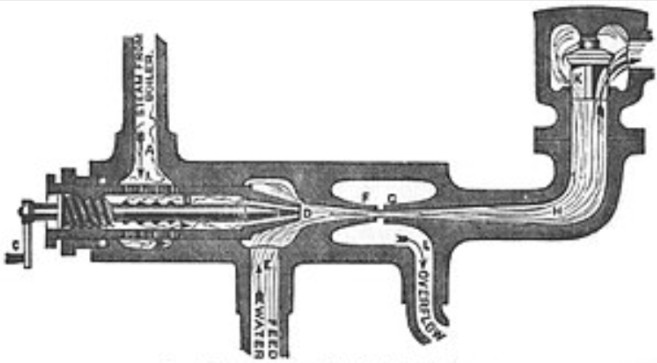

Steam injectors of the make-up system for steam boilers. Working principle and design

This type of steam injector operates on the principle of a steam jet pump, built on the basis of a classic steam ejector, and works with high-pressure (high-grade) high-pressure steam, which is actually supplied from the same steam boiler into which make-up water is pumped. The fact is that steam boilers often operate under very high pressure, up to 25 MPa, and sometimes up to 40 MPa. In such a steam boiler, it is not a trivial task to pump makeup water with a conventional centrifugal water pump; such a high discharge pressure is only possible for much more complex and expensive gear, plunger or piston pumps. Therefore, the use of a simple in design, cheap and highly reliable steam jet injector as boiler equipment is the most justified solution from a technical and economic point of view.

The principle of operation of a steam jet injector is built according to the scheme of a classic steam ejector. A high-speed jet of live steam supplied through the steam line, flowing out of the nozzle, draws in (sucks in) make-up water from the supply line, which, in the composition of the steam-water mixture, enters the expanding chamber of the diffuser. In the diffuser, the steam-water mixture, according to Bernoulli's law, acquires a high pressure necessary to overcome the back pressure from the inside of the steam boiler. Upon reaching the required pressure of the medium in the diffuser, the steam-water mixture is injected into the steam boiler through the check valve.

Rice. Steam injector diagram of a steam boiler water make-up system

Steam injectors for water heating systems. Working principle and design

This type of steam injectors operates with low-grade saturated steam, as a rule, in subsystems for recovering the heat of secondary boiling condensate steam. Such secondary steam is formed in the systems for removing superheated condensate of steam power plants and heat exchangers, with subcritical parameters of the working steam.

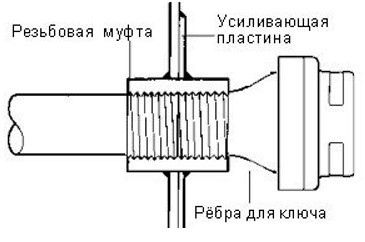

The design of this type of injection device is much simpler. By and large, they represent a nozzle-nozzle on the steam line, which is put inside a container with heated water. The shape and design of such an injection nozzle is optimized for the most uniform dispersion of the injected steam, in order to optimize heat transfer and minimize the noise effect caused during the injection of steam into heated water. The quiet operation of steam injectors is one of their important operational parameters.

Water heating steam injectors are commonly used for:

- utilization of secondary steam energy for heating the feed water of steam boilers, including for preliminary removal of soluble oxygen from it;

- recovery of the energy of secondary steam for heating water in hot water supply systems, or water heating.

Steam injectors operate in a corrosive hot water vapor environment at high pressures. Therefore, as a rule, they must be made by the method of one-piece casting (without welded seams), from corrosion-resistant alloys: high-alloy stainless steel or brass.

Rice. A diagram of the installation of a steam injector through the wall of the water tank in the water heating system.

Parameters for the selection of steam injectors

The defining parameters for the selection of steam injectors are:

- intended purpose: for systems of water make-up of steam boilers, or for systems of utilization of steam for the purpose of heating water;

- maximum working pressure, in MPa;

- the maximum temperature of the heated water at which the injection sound is muffled. This parameter characterizes the silent operation of the device (for water heating systems with secondary steam).

- conditions of connection to the steam pipeline: by bore diameter and thread size.

Steam injectors in the range of OPEKS Energosystems

Specializing in the sale of heat exchange and other heating equipment of its own production, OPEKS Energosystems strives to offer the widest possible range of various equipment to best meet the needs of its customers. In the segment of steam injectors, we offer products from one of the recognized world leaders in the heating equipment market, the Japanese company Yoshitake.

Among the offered models of Yoshitake steam injectors, our customers will be able to choose options for both make-up systems for steam boilers and systems for utilizing secondary steam for heating water. All offered models of Yoshitake steam injectors are characterized by the impeccable quality of a world-renowned manufacturer, made of solid stainless steel or brass, strictly correspond to the declared operational parameters, their design is optimized to ensure the most silent operation during steam injection into heated water.